fluid overboard. The leading edge flaps extend to the

full down position and trailing edge flaps to the 1/2

down position. The aileron drooping feature does not

operate when the flaps are lowered by the emergency

flap system.

SEMI-INDEPENDENT FLAP AND SLAT

SYSTEM

This system consists of semi-independent flap

and slat systems, which raise and lower using

hydraulic motors drive units, torque tubes, and screw

jack-type actuators.

Flap System

The flaps divide into two panels per wing at the

wing-fold joint. Each panel is supported by two sets

of tracks and rollers that are driven by two ball screw

actuators.

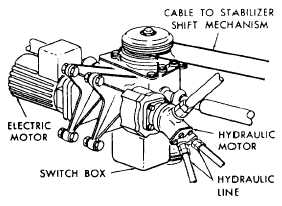

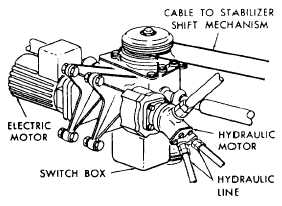

Pressure from the combined hydraulic

system powers the flap drive motor and gearbox

assembly, shown in figure 9-35.

If the combined hydraulic system fails, a

hydraulic brake locks the hydraulic motor, and an

emergency electric motor provides continued

operation. Emergency flap extension and retraction is

controlled by placing the EMERG FLAP switch on

the throttle quadrant at either UP or DN.

Cam-operated switches within the flap drive gearbox

provide input signals to show the flap position on the

cockpit-integrated position indicator.

Operation of the flap control handle energizes the

solenoid-operated flap selector valve, directing

hydraulic pressure to the extend or retract lines of the

flap drive motor.

The wings must be spread and

locked to provide a complete electrical circuit through

the wing unlock relay to the selector valve.

Figure 9-35.—Flap drive gearbox.

Placing the flap control handle to the TAKEOFF

position completes the electrical circuit through the

30-degree switch and cam-operated flap drive

gearbox limit switch to the selector valve. Pressure

ports to the down side of the high-speed hydraulic

motor, which drives the gearbox.

The flap drive

gearbox, through a series of torque tubes and offset

gearboxes, drives all eight flap actuators.

The flap actuators, shown in figure 9-34, drive the

carriage and attaching flaps out and down to the

30-degree position. The limit switch in the flap drive

gearbox opens, de-energizing the selector valve

circuit, allowing the valve shuttle to return to neutral,

blocking flow to the motor, and preventing further

flap extension.

Placing the flap control handle to LAND

mechanically closes the 40-degree down flap handle

switch. The electrical circuit to the selector valve

completes, this time through the now closed

40-degree down limit switch in the flap drive gearbox.

The flaps will extend to 40 degrees, and the electrical

circuit will be broken by the action of the limit switch.

Moving the flap control handle to the TAKEOFF

or UP position will energize the opposite solenoid of

the flap selector valve and port pressure to the retract

side of the flap hydraulic motor. If the TAKEOFF

position is selected, a limit switch will again halt flap

movement at the 30-degree position. If UP is

selected, retraction will be halted when the flaps reach

the full up position. Stopping the flaps is a function

of the flaps up limit switch. At the same time, linkage

from the up limit switch actuates a second switch to

complete the electrical circuit to the flap hydraulic

motor brake valve. The energized valve blocks

combined hydraulic system pressure that is holding

the hydraulic brake in the unlocked position. The

brake locks the hydraulic motor, which, in turn, locks

the flaps in the up position.

If combined hydraulic system pressure fails and

the emergency flap switch is used, the flap action is

powered by the electric motor. See figure 9-35. The

flap hydraulic brake valve is energized, and the

pressure holding the spring-loaded hydraulic motor

brake unlocked will port to return. The brake is then

free to lock the motor and input shaft.

The electric motor now drives the flap gearbox

and associated linkage, bypassing the locked

hydraulic motor.

This action occurs until the flaps

reach a 40-degree trailing edge down position. Limit

9-42