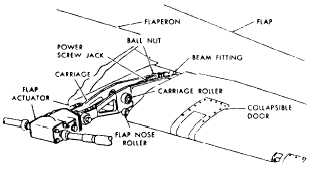

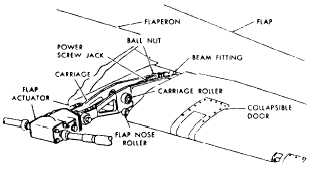

end of the ball screw (screw jack shaft) and

mechanical stops on the actuator body protect the

actuator against possible overtravel during flap

extension and retraction.

Figure 9-36.—Flap actuator.

switches shut the electric motor off when the flaps

reach the 40-degree down and full up positions.

FLAP ACTUATOR.—The flap actuator shifts

rotary motion of the input shaft to linear flap motion,

using bevel gears and the ball screw jack mechanism.

See figure 9-36. A load-sensing device in each flap

actuator operates a clutch assembly to stall out the

flap system if it is overloaded. An impact plate at the

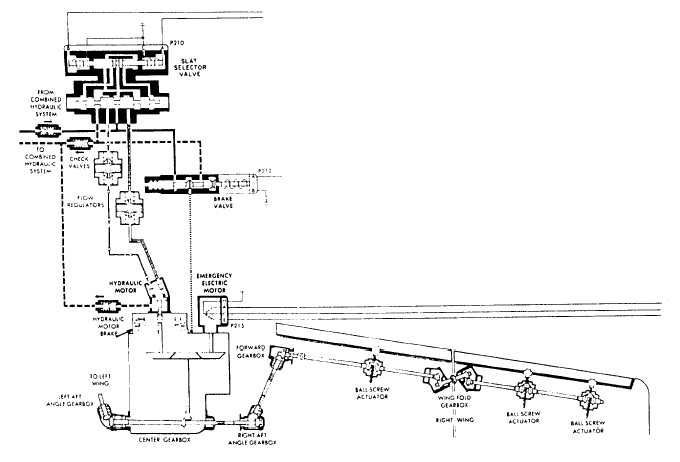

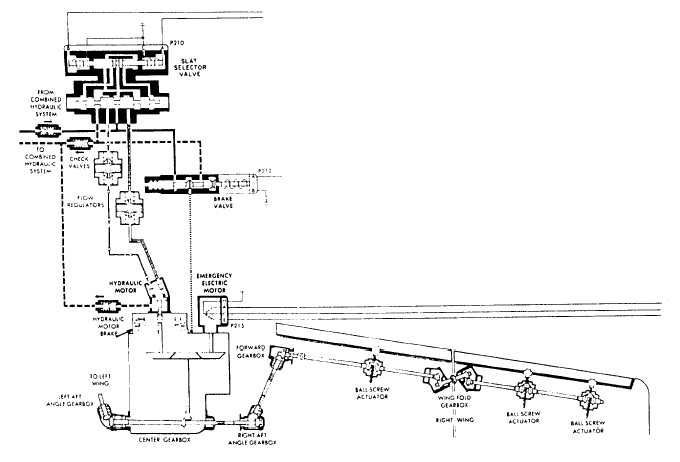

OFFSET GEARBOXES.—The eight offset

gearboxes in the flap system transmit power produced

by the flap drive gearbox around wing structure

obstacles and compensate for wing angularity. They

also reduce the flap drive gearbox speed of 1,080 rpm

to about 550 rpm at the outboard actuators.

FLAP WING-FOLD SHAFT.—A wing-fold

shaft consists of two interlocking splined sections and

two universal joints connected to quill shafts. It

provides a telescoping fold joint in the flap drive

system linkage between the inboard and outboard

wing panels.

Slat System

The slat system, shown

additional lift and stability

speeds in the same manner

in figure 9-37, provides

to the aircraft at lower

as the leading edge flap

Figure 9-37.—Slat drive system.

9-43