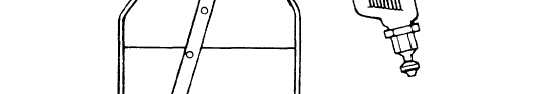

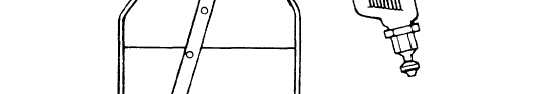

Figure 14-33.—Suction-feed spray gun.

SUCTION FEED.—The suction-feed spray gun

is designed for small jobs. The container for the paint

is connected to the spray gun by a quick-disconnect

fitting, as shown in figure 14-33. The capacity of this

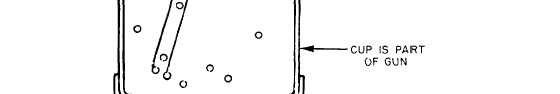

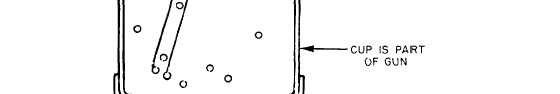

container is approximately 1 quart. The fluid tip of

this type of spray gun protrudes through the air cap, as

shown in figure 14-34. The air pressure rushing past

the fluid tip causes a low-pressure area in front of the

tip. This causes paint to be drawn up through the fluid

tip, where it is atomized outside the cap by the air

pressure.

PRESSURE FEED.—The pressure-feed spray

gun is designed for use on large jobs where a large

amount of spray material is to be used. The spray

material is supplied to the gun through a hose from a

pressurized tank.

This spray gun is designed to

operate on high-volume, low-pressure air. This type

of equipment eliminates the evaporation of the

volatile substances of the mixture before striking the

surface because the paint and air are mixed in the

tanks. In other words, a wetter coating is applied.

Spray Gun Maintenance

Fluid leakage at the front of the gun is an

indication that the fluid needle is not seating properly.

This may be caused by a fleck of dried material in the

nozzle, or the fluid needle packing may be too tight.

It may also be caused by a bent fluid needle, a broken

fluid needle spring, or the wrong size fluid needle for

the fluid tip.

Air leakage results from an improperly set air

valve.

This may be caused by a bent valve stem,

broken spring, or damaged valve or valve seat.

Jerky or fluttering spray is caused by an obstructed

fluid passage, loose tip, damaged seat, or air in the fluid

line. Air can be inducted into the line from several

sources: a loose packing nut, dried packing, loose or

damaged coupling nut, loose or damaged fluid tube, or

the cup tipped too far. See figure 14-35. Faulty spray

14-38