Zinc Chromate Primer TT-P-1757

Zinc chromate primer is intended for use as a

general-purpose interior protective coating for metal

surfaces. Depending on the location, zinc chromate

primer may or may not require a topcoat. Primer is

relatively easy to apply and remove. Zinc chromate

primer is a single component. You should thin primer

with TT-T-548 toluene or TT-M-261 methyl ethyl

ketone. Do not use zinc chromate primer on exterior

aircraft surfaces, wheel wells, wing butts, or in areas that

are exposed to temperatures exceeding 175°F (79.4°C).

Enamel Finishes

Most enamel finishes used on aircraft surfaces are

baked finishes that cannot be touched up by

organizational or intermediate levels of maintenance.

Minor damage to conventional enamel finishes

ordinarily used on engine housings is repaired with

epoxy topcoat material or air-drying enamel.

Elastomeric Rain Erosion-Resistant Coating

MIL-C-7439

Elastomeric coatings are used as a coating system

to protect the exterior laminated plastic parts of

high-speed aircraft, missiles, and helicopter rotor

blades from rain erosion. They offer good resistance

to the effects of weather and aromatic fuels.

Excellent adhesion is obtained after a 7-day drying

period.

Repairs to these coatings in the field are

impracticable because of the long curing time. Kits

are available to repair coatings where limited touchup

is required. These kits contain a primer, neoprene

topcoat, and antistatic coating. If the radome or

leading edge coatings are in bad condition, they

should be stripped completely and recoated with

epoxy primer and acrylic topcoat as a temporary

measure. If schedules and conditions permit adequate

curing of elastomeric coatings, these original coatings

may be replaced.

The repair kits are normally bought open

purchase to ensure that fresh materials are available.

They should be stored in a cool place or refrigerated.

Heat accelerates their aging. Stripping fiber glass

surfaces should be done according to the current

maintenance instructions. Elastomeric coatings are

toxic and flammable and must be used with care.

General Safety Precautions for Painting

General safety precautions for all painting as well

as those for special types of paints must be observed.

These precautions include the following:

No eating, drinking, or smoking is allowed in

areas where paint or solvent is being used.

Prolonged breathing of vapors from organic

solvent or materials containing organic solvent is

dangerous. Prolonged skin contact with organic

solvents or materials containing organic solvents can

have a toxic effect on affected skin areas.

PAINTING SPECIFICATIONS

Specifications for the location, colors, and layout

for letters and numbers can be found in Paint

Schemes and Exterior Markings for U.S. Navy and

Marine Corps Aircraft, MIL-STD-2161(AS). Other

painting specifications that you may need to perform

your duties are Finishes, Organic, Weapons System,

MIL-F-18264D(AS); and Marking and Exterior

Finish Colors for Airplanes, MIL-M-25047C(ASG).

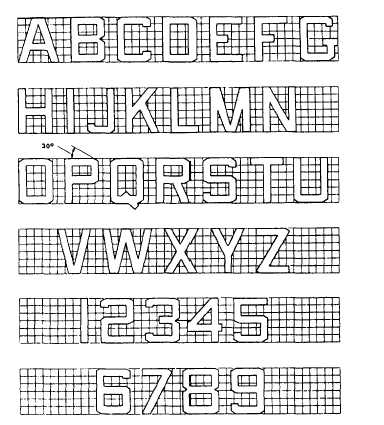

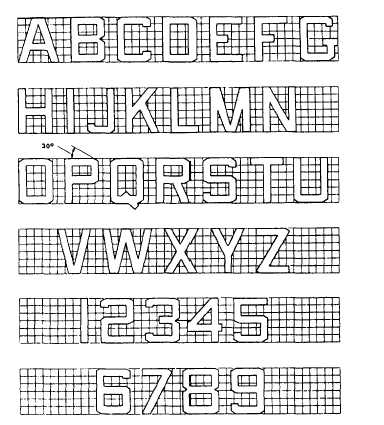

Numbers and Letters

The layout for standard military letters and

numbers is shown in figure 14-31. The specifications

of the form for letters follows:

Figure 14-31.—Forms of letters and numerals.

14-35