coat is too thin, the remover may dry on the surface of

the metal.

You should allow the stripper to wrinkle and

lift the paint. This may take from 10 minutes to

40 minutes, depending upon the temperature, the

humidity, and the condition of the paint.

You should remove loosened paint and residual

paint remover by washing and scrubbing the surface

with fresh water, nonmetallic scrapers, fiber brushes,

or abrasive pads. If water spray is available, use a

low- to medium-pressure stream of water directly on

the surface while it is being scrubbed.

After you thoroughly clean the surface, you

should remove the masking materials and remove any

residual paint.

Rinse the surface with a freshwater and alkaline

solution (1 part MIL-C-25769 to 9 parts water) to

neutralize the paint remover.

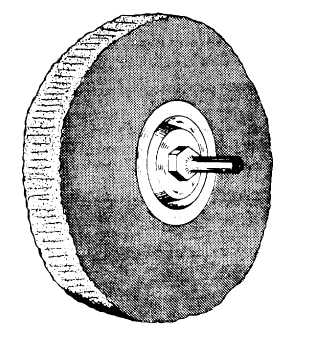

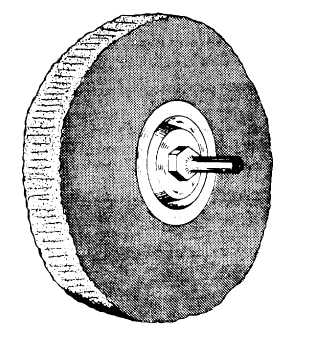

FLAP BRUSH.—Paint can be mechanically

removed with a flap brush. The brush consists of

many nonwoven, nonmetallic nylon flaps bonded to a

fiber core. The brush assembly (fig. 14-29) is made

up of a flap brush, flanges, and a mandrel. It should

be operated by a NO LOAD, 3200 rpm, pneumatic

drill motor. The direction of rotation is indicated by

an arrow imprinted on the side of the core. When a

flap brush has been worn down to within 2 inches

from the center of the hub, you should replace it.

Continued use beyond this limit may cause gouging

due to loss of flexibility of the fiber. When you use a

flap brush, apply minimum pressure to remove the

maximum amount of paint and the minimum amount

of metal. Excessive pressure will cause some paints

to melt, gum up, and streak. Eye protection should be

worn when you are operating a flap brush.

SCUFF SANDING.—Aged paint surfaces

should be scuff sanded to ensure the adhesion of the

overcoating paint. Scuff sanding is the roughening of

a paint surface as evidenced by a significant reduction

of the gloss. To scuff sand, you should use aluminum

oxide cloth, abrasive mats, or an oscillating sander

with aluminum oxide cloth. Scuff sanding to a depth

greater than necessary may result in complete

removal of the paint. This situation will expose the

underlying metal, and corrosion may develop.

Unevenly matched faying surface joints or fasteners

and sharply protruding objects or corners should be

scuff sanded by hand to avoid sanding through the

paint. After sanding, you should remove the residue

with a clean, cotton cheese cloth dampened with

MIL-T-81772 thinner.

PAINT FEATHERING.—You should feather

the paint along the edge of an area that has been

chemically stripped to ensure a smooth, overlapping

transition between the old and new paint surfaces.

The smooth overlapping paint film will prevent soil

from accumulating in the junction between the old

and new paint films.

Feathering should be

accomplished with 280 or 320 grit aluminum oxide

cloth or a flap brush. The major portion of thick paint

films may be removed with an oscillating sander with

240 or finer grit aluminum oxide cloth. Do not allow

the oscillating sander to touch bare metal. The

contact between an operating sander and bare metal

will damage the metal, which, in turn, may cause

future corrosion. The oscillating sander should not be

used after first indications of primer exposure. You

should use a flap brush or hand-held 240 grit or finer

aluminum oxide cloth for final feathering operations.

TREAT AND SEAL.—Chemical conversion

treatment is an extremely important part of the

corrosion control process. Properly applied chemical

treatments impart corrosion resistance to metal. It

also improves the adhesion of the paint system. You

should use chemical conversion coating materials

according to the procedures outlined in the NA

01-1A-509.

Figure 14-29.—Flap brush with mandrel.

14-31