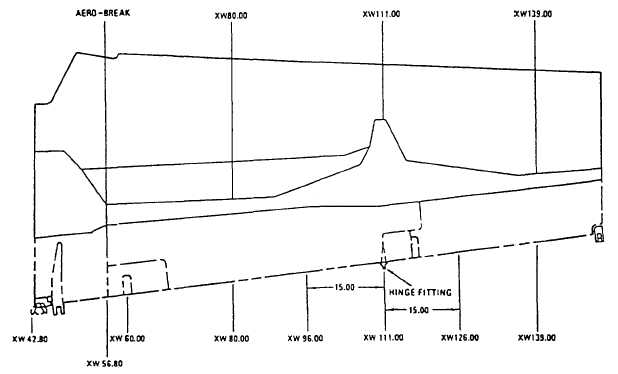

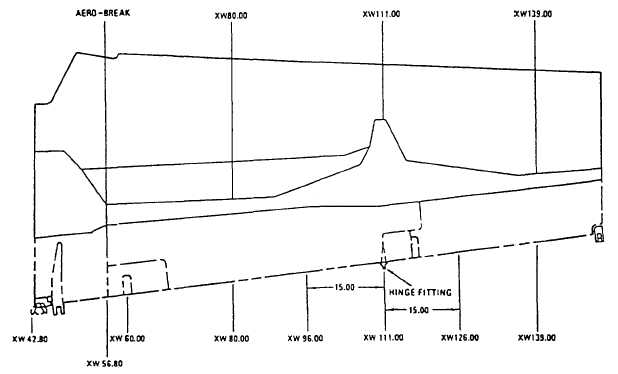

Figure 14-27.—Repair zones.

critical zones include leading edges of wings and

tails, forward nacelles and inlet areas, forward

fuselages, and overwing areas of the fuselage. The

least critical zones include trailing edges and aft

fuselage areas.

Repair Tools

Drill motors should be capable of speeds of 2,000

to 5,000 rpm. These drills should be equipped with

feed rate limiting surge controls to prevent backside

breakout caused by feeding the drill too fast and

excessive heat buildup from feeding the drill too slow.

Feed rates should not exceed 30 seconds per inch,

with 10 to 15 seconds per inch producing the best

results on graphite-epoxy composites. The drill

should be turning full speed prior to surface contact

and during withdrawal from completed holes. These

holes should be drilled slightly undersize and reamed

to the required size. The various types of drill bits

used for drilling composites are either twist, flat

fluted/spade/dagger, single flute, or piloted

countersink, and they are made out of carbide or

carbon steel.

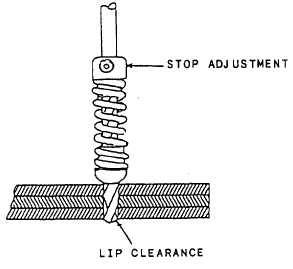

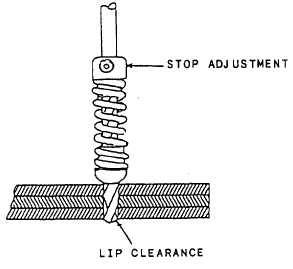

A drill stop (fig. 14-28) is an adjustable spring

damper that is attached to the drill bit shank. This

mechanically stops the drill at a predetermined depth

prior to exiting the material backside, thus reducing

backside breakout caused by the follow through.

Firm pressure is required to overcome this spring

tension for the drill to penetrate the laminates

backside.

Routers are high-speed, hand-held, portable

cutters used for removing damaged skin or core

materials. They are designed to operate on shop air at

Figure 14-28.—Drill stop.

14-27