Figure 3-19.—Stationary pit-type scales.

of gravity of aircraft (as well as wheeled vehicles and

cargo loads). The complete system is portable and

includes a trailer for storage and transport, or it is

mounted on a single 88- by 108-inch pallet. Typical

installation setup time by two men is 30 minutes.

HEAVY-DUTY PORTABLE SCALES.—This

system is designed to provide weight only. Wheeled

vehicles and cargo may also be weighed on these scales.

The complete system is portable and completely

self-contained. Platform size is small, but it may be

increased by connecting two scales with a factory

provided charnel. Because of the small platforms, you

must exercise care when using this system. Typical

installation setup time by two men is 10 minutes.

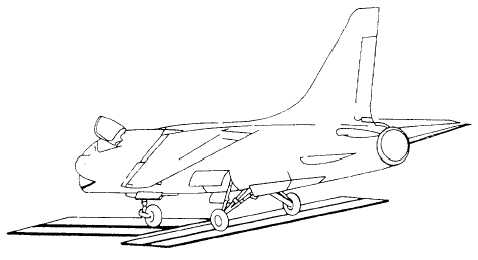

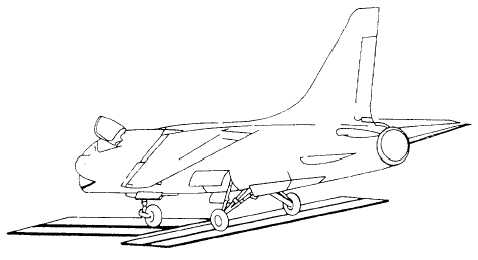

STATIONARY PIT-TYPE SCALlES.—Most of

the large scales are of the stationary-beam and

lever-balance type. See figure 3-19. These scales are

commonly flush floor installations, although some are

used as surface-type portable scales. The flush floor

installation generally is in a permanent location, and the

aircraft must be taken to it. However, some flush floor

scales have the capability to be removed from their

installations, when necessary, and taken to the aircraft.

These scales are usually expensive and normally require

a special building or hangar.

Weighing with calibrated scales is the only sure

method of obtaining an accurate basic weight and center

of gravity location on an aircraft. The large stationary

pit-type scales must be calibrated or certified correct at

least once every 12 months. Heavy-duty portable scales

and MEWS scales must be calibrated at least once every

6 months.

Weighing Accessory Kit

It maybe necessary to prepare special devices that

will aid in taking measurements and leveling specific

types of aircraft. To measure such data as lengths,

angles, and densities, weight and balance personnel

require accessories such as levels, plumb bobs,

measuring tapes, chalk lines, and hydrometers. Some

types of aircraft require special equipment. The

equipment will be assembled into a specific type of

aircraft kit.

SPIRIT LEVEL.—At least one spirit level is

required for leveling most aircraft. Two levels are

generally recommended. Use one 24-inch level for

spanning distances between leveling lugs. Use a 6-inch

level for use in places where sufficient space is not

available for seating a 24-inch level. The levels should

be a machinists’ bench type of first-class quality.

LEVELING BARS.—Several leveling bars of

varying lengths are needed for spanning the distances

between leveling lugs. One set of bars usually comes

with the weighing kit normally maintained by each

Naval Aviation Depot (NADEP).

PLUMB BOBS.—Plumb bobs are used to project

points on the aircraft onto the floor for measuring

dimensions in a level plane. Each pIumb bob should

have a slot in the head so that excess string can be wound

around the neck. Plumb bobs are normally included in

the weighing kit.

STEEL TAPES.—Use a steel tape 600 inches in

length and graduated in inches and tenths of inches. All

weighing dimensions must be read to one-tenth of an

3-30