217.210

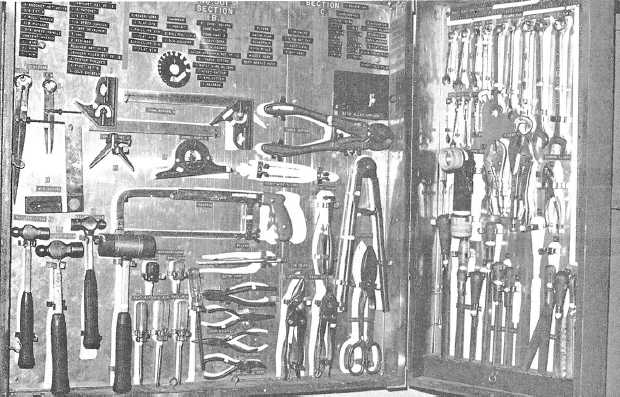

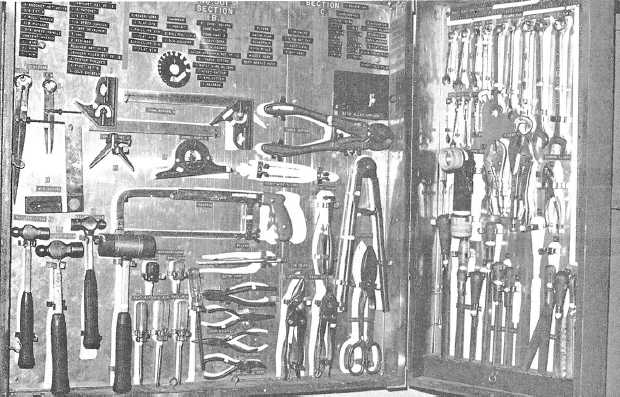

Figure 3-1.—Typica1 silhouette toolbox.

6. That tools of poor quality are reported to

FLEMATSUPPO via CAT II QDRs.

7. That VIDS/MAFs are annotated with a tool

container number and appropriate initials are obtained

following task completion/work stoppage.

8. That the department’s tool control environment is

maintained when work is to be performed by contractor

maintenance teams or depot field teams. A QAR will

brief field team/contractor supervisor/ leader(s) upon

their arrival regarding the activity’s TCP. Depot teams

working in O- or I-level facilities will comply with the

host activity’s TCP.

WORK CENTER RESPONSIBILITIES

All

work

center

supervisors

have

specific

responsibilities under the TCP. All tool containers

should have a lock and key as part of their inventory.

The supervisor should be aware of the location of each

container’s keys and have a way of controlling them.

When work is to be completed away from the work

spaces (for example, the flight line/flight deck),

complete tool containers, not a handful of tools, should

be taken to the job. If more tools are needed than the

tool container contains, tool tags can be used to check

out tools from other tool containers in the work center

or from another work center. The following is a list of

additional responsibilities of the work center

supervisor:

1. Upon task assignment, note the number of the

tool container on copy 1 of the VIDS/MAF, left of the

accumulated work hours section. A sight inventory will

be conducted by the technician prior to commencement

of each task, and all shortages will be noted. Every

measure must be taken to ensure that missing tools do

not become a cause of FOD. Inventories will also be

performed before a shift change, when work stoppage

occurs, after maintenance has been completed, and

before conducting an operational systems check on the

equipment.

2. When all tools are accounted for and all

maintenance actions have been completed, the work

center supervisor signs the VIDS/MAF, signifying that

maintenance has been completed and that all tools

have been accounted for.

3. If any tool is found to be missing during the

required inventories, conduct an immediate search

prior

3-2