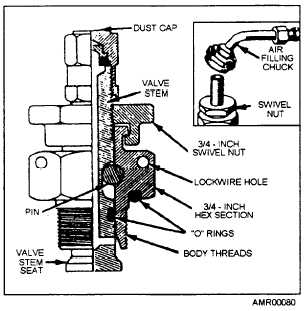

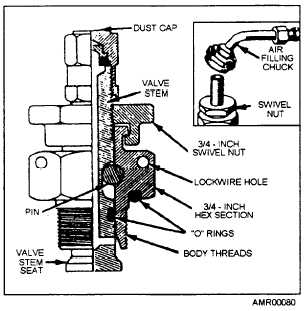

Figure 5-8.—High-pressure air valve, MS 28889-1.

caution. To release the air pressure from a system

equipped with a high-pressure air valve, you should

remove the dust cap from the valve and release the

pressure by slowly turning the swivel nut

counterclockwise.

NOTE: Dust covers are not used in most operating

squadrons because they are a foreign object damage

(FOD) hazard.

CAUTION

When loosening the swivel nut, you should

make sure that the hex body nut is either

lockwired in place or held tight with a

wrench. If it were to be loosened before the

air pressure is relieved, serious injury to per-

sonnel may result.

Low pressure indicates a leak in the system. This

leak must be found and corrected. When a leaking,

high-pressure air valve must be replaced, a new

packing must be installed with the replacement air

valve assembly. Ensure the required torque, as

required by the MIM, is applied to the hex body. After

the hex body is torqued, it is lockwired to the

component or surrounding structure, as specified in

the MIM, by using the holes provided in the hex body

nut.

When the correct pressure has been reached in the

system that is being serviced, you should secure the air

valve by tightening the swivel nut in a clockwise

direction. Once again, torque the swivel nut to the

required torque listed in the MIM.

After using the high-pressure air valve, you should

secure the pressure source, remove the air/nitrogen

pressure charging chuck, and replace the valve cap.

Install the valve cap fingertight.

Air or Nitrogen Servicing Trailer

A servicing trailer, similar to the one in figure 5-9,

is found at most naval air activities for servicing

aircraft hydraulic and pneumatic systems. This trailer

carries six air or nitrogen storage cylinders and the

necessary flow-controlling mechanisms. The trailer

has a 30-foot hose stowed in a box that is mounted

between the top two bottles.

The air or nitrogen servicing trailer has a purifier

(dehydrator) assembly. This purifier assembly is

essentially a reservoir that contains a chemical drying

agent. The chemical drier removes moisture that may

have adhered to the valves or have been accidentally

introduced into the system. The chemical is contained

in a metal cartridge or can, which is changed

periodically. The gas passes through the drier just

before it enters the servicing hose. The trailer has a set

of manifold control valves and two regulator valves.

The bottle on the air or nitrogen servicing trailer may

be recharged by using a high-pressure compressor.

NOTE: When recharging the cylinders on the air

or nitrogen servicing trailer, you should ensure that the

cylinder pressure does not exceed the pressure

specified for the equipment being recharged.

When operating the servicing trailer, you should

observe the following safety precautions.

When a system or component is being charged,

only a qualified licensed operator should operate the

trailer. Complete familiarity with the trailer is a basic

prerequisite to ensure safe operating techniques.

The servicing hose end and installation

connection fitting should be thoroughly inspected

before servicing, and any particles of foreign material

removed.

Never charge a system or component without the

proper fusible safety plug and blowout disc in the trailer

charging system.

5-13