Q74. Information regarding corrosion removal

limitations can be found in what publications?

CHEMICAL SURFACE TREATMENT

LEARNING OBJECTIVE: Define the purpose

for chemically preparing a surface for priming

and painting.

Chemical conversion coatings increase a surface’s

resistance to corrosion and improve paint bonding on

the surface.

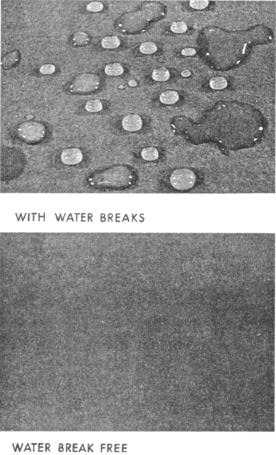

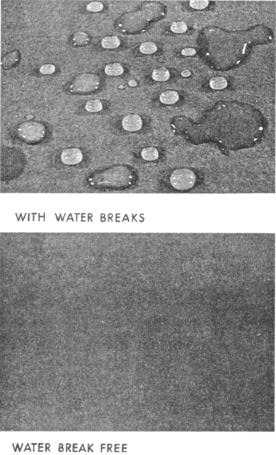

The metal to be treated must be cleaned to a water

breakfree surface (fig. 4-30). Metal surfaces not free

of water breaks must be recleaned with a solution of 1

part MIL-C-43616 or MIL-C-25769 aircraft cleaning

compound to 16 parts of water, and then rinsed with

water. Surfaces that have been waxed, particularly

with silicone wax, may require special cleaning. After

cleaning and removal of surface oxides, aluminum

should be treated with MIL-C-81706 and magnesium

with MIL-M-3171, type VI, chemical conversion

coating material.

214.248

Figure 4-30.—Water break comparison.

CAUTION

Personnel must wear protective clothing,

rubber gloves, and chemical goggles when

using a solution of MIL-C-81706 and MIL-

M-3171 or serious injury could result.

Apply these chemical conversion coatings

immediately after cleaning the surface to a water

breakfree surface and while the surface is still wet.

Apply these coatings by brush, nonatomizing spray, or

sponge stick moistener. The sponge stick moistener is

particularly useful for small areas.

Soluble salt residues that remain on the surface

after treatment accelerate corrosion and can cause

blistering of paint finishes. Thus, complete rinsing

with fresh water following the chemical treatment is

very important. Flush the chemical with free-flowing

water only. Allow the chemical conversion coated

surface to dry (usually 30 minutes) before painting. Do

NOT wipe the surface with a damp cloth or brush, as

this will degrade or remove the chemical conversion

coating.

Chemical conversion coatings are often damaged

during aircraft maintenance, or they may be

contaminated by grease, oil, or other foreign matter.

Therefore, the treated surface should be painted soon

after treating to obtain the best results.

CHEMICAL CONVERSION OF

ALUMINUM ALLOYS

The procedure to be used for the chemical

conversion of aluminum alloys is as follows: Apply

the conversion coating material, MIL-C-81706 (Form

V [powdered] is preferred, Form III [premixed] is an

alternate), until you obtain a golden iridescent color.

Immediately rinse the chemical from the surface with

large amounts of fresh water when you obtain the

proper color conversion. This rinsing stops the

chemical action and minimizes solution entrapment.

Failure to rinse may accelerate corrosion and reduce

paint bonding. If a long period of contact before

rinsing is allowed, a powdery, coated surface may be

the result.

CHEMICAL CONVERSION OF

MAGNESIUM ALLOYS

The procedure for the chemical conversion of

magnesium alloys is as follows: Apply the conversion

4-45