SURFACE PREPARATION

The effectiveness of any paint finish and its bond

to the surface depends upon the careful preparation of

the damaged surface before touch-up. The touch-up

paint should overlap onto the existing good paint

finish. The touch-up materials will not bond to glossy

finishes, so the finishes must be prepared. Also, any

edges of the existing film will show through the

overlap unless they are smoothed out.

To break the gloss of existing finishes and to

feather (smooth out) the edges for overlap, you should

scuff sand by using 240 or 320 grit aluminum oxide

cloth. After sanding, use a water rinse to remove the

abrasive residues.

You should remove any loosened seam sealants in

the area to be touched up and replace them as

necessary. Also, resecure any loose rubber seals by

using the type of adhesive specified in the applicable

MIM.

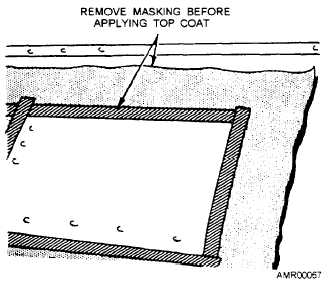

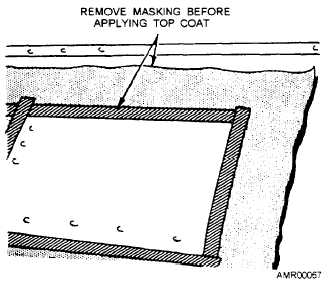

Then outline the area to be painted with tape and

masking paper, as shown in figure 4-32. This protects

the adjoining surfaces from overspraying and

unwanted paint buildup.

TOUCH-UP PROCEDURES

A standardized paint system for O- and I-level

painting and paint touch-up is presented in NAVAIR

01-1A-509.

Standardized exterior paint touch-up systems for

organizational and intermediate levels of maintenance

consist of an epoxy primer (MIL-P-23377, type I or

type II, as applicable) overcoated with aliphatic

polyurethane (MIL-C-85285). Paint systems are

identified by a decal or stencil located on the right side

of the aft fuselage.

Standardized interior paint touch-up systems for

O- and I-level maintenance consist of zinc chromate

primer (TT-P-1757). Paint materials that are within

their original shelf life or within an extended shelf life

are preferred. However, if materials are beyond shelf

life date, test them by using a small sample of scrap

aluminum.

The following paragraphs furnish the basic

information for identifying and applying the standard

touch-up paint systems. Complete information on the

types and applications of aircraft paint systems is

contained in NAVAIR 01-1A-509.

Figure 4-32.—Masking before paint touch-up.

Epoxy-Polyamide Primer

(MIL-P-23377)

The epoxy-polyamide primer is supplied as a

two-part kit. Each part must be stirred or shaken

thoroughly and separately before they are mixed

together. One part contains the pigment particles in an

epoxy vehicle. The other part is composed of a clear

polyamide solution that functions as a hardener for the

epoxy solution. This primer is supplied by various

manufacturers. You should mix only as much primer

as needed. The storage life of the primer is limited after

it is mixed to the amount that can be used in 4 hours.

Refer to NAVAIR 01-1A-509 for specifics on mixing

these two components.

Zinc Chromate Primer

Zinc chromate primer (TT-P-1757) is a

general-purpose, interior, protective coating for metal

surfaces. Depending upon the location, zinc chromate

primer may or may not require a topcoat. Zinc

chromate primer is easy to apply or remove as it is a

single component. There is no thinning required for

brush or roller application however, for spray

application, thin this primer with MIL-T-81772. Do

not use zinc chromate primer on exterior aircraft

surfaces, including wheel wells and wing butts, and in

areas that are exposed to temperatures exceeding

175°F (79.4°C).

Polyurethane Finish Systems

You must have a physical examination before you

can work with polyurethane coatings. Also, you must

4-48