operated. In addition, all of the elevators are rated for a

9,000-pound load capacity, and the elevator trunks have

side-loading capabilities at several magazine levels.

Except for minor differences, the elevators aboard

the USS Eisenhower and the USS Carl Vinson are

almost identical to those aboard the USS Nimitz.

The foIlowing text contains a brief description of

the two major classifications (lower-stage and

upper-stage) of weapons elevators. Regardless of the

type of installation a weapons elevator provides a safe

and efficient means for you to handle weapons and

weapons components among the magazines and the

various assembly, staging, and arming areas within the

ship.

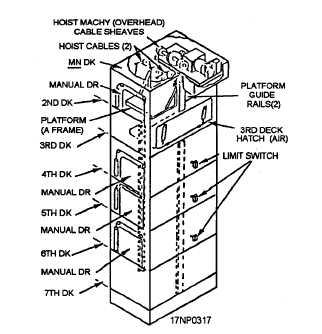

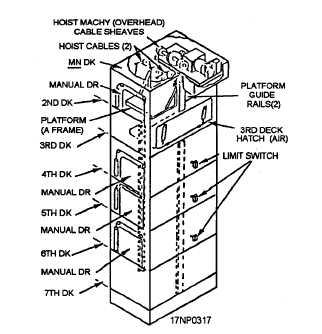

LOWER-STAGE WEAPONS ELEVATORS

(5,500 POUNDS).— The 5,500-pound, lower-stage,

weapons elevator (fig. 11-15) services magazines and

ammunition handling areas from the 7th-deck level up

to and including the 2nd-deck level. The components

of the elevator include an electrically powered,

multiple-drum winch, an elevator platform, an enclosed,

watertight, vertical trunk with doors located at the levels

and stations serviced, and a semiautomatic control

system.

Ramps are used to bridge the gaps in the door

opening between the elevator platform and the deck.

These allow you to load or unload the elevator platform

by using forklift trucks or wheeled skids.

Figure 11-15.—Typical 5,000-pound lower-stage, weapons

elevator.

Each lower-stage elevator is equipped with a

broken-rope safety device, a down-speed governor

device, and slack cable-sensing devices. The

broken-rope safety device is mounted on the elevator

platform assembly.

If any one of the platform

suspension ropes break, a roller-wedging mechanism

automatically operates to lock the platform to the guide

rails.

A counterweight-type governor device for limiting

speed of elevator down travel is located in the upper

end of the elevator trunk. The governor is operated by

a wire rope connected to a lever of the broken-rope

safety device on the elevator platform. Then, the rope

is passed over the governor sheave and attached to the

governor spooling drum on the hoisting winch.

Excessive down speed causes the governor limit switch

to shutoff the power to the hoist motor and electric

brake. Loss of electric power causes the brake to

automatically stop the elevator. If the brake fails to stop

the elevator, the governor sheave grips the governor

rope, causing the broken-rope safety device to stop the

elevator.

A slack, cable-sensing, safety device is provided for

each suspension rope and the governor rope. Located

in the area between the winch drums and the overhead

sheaves, these devices function by applying a

spring-loaded follower roller to the wire rope. Rope

slack causes a proximity switch to shutoff electrical

power to the hoisting winch motor and brake, which

stops the elevator.

If the elevator overtravels upward beyond the

maximum up stop position, an overtravel limit switch is

actuated. This stops the elevator by shutting off power

to the hoisting winch motor and brake.

If the elevator overtravels downward beyond the

hold deck loading station level, the platform is stopped

by spring bumpers in the bottom of the elevator trunk.

The slack-cable switches are actuated to cut off power

to the hoisting winch motor and brake.

An operator-attended control panel is located next

to all elevator doors. All operator control panels have a

display of selector switches, pushbuttons, and indicator

lamps suited for the control functions required at the

station served. All control panels have an emergency

stop-run switch from which all operations of the

elevator can be stopped.

The main operator control panel and electrical

power switch are located at the 2d deck-level station.

An elevator can be dispatched to another level from any

operator control panel. The lower-stage elevator control

11-24