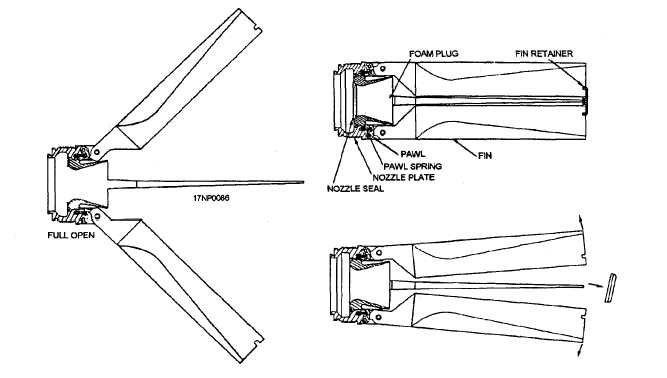

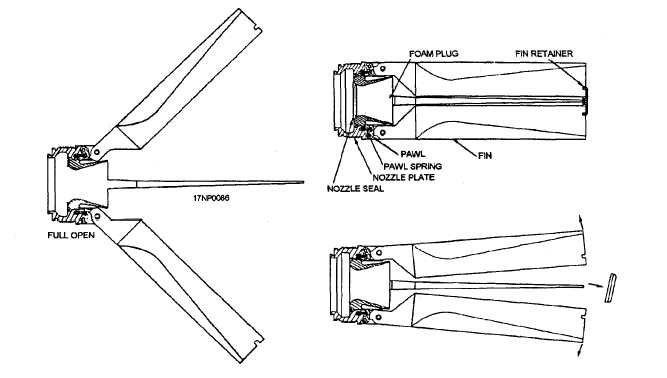

Figure 2-9.—Mk 16 motor, nozzle, and fin assembly.

The nozzle inserts of the Mk 4 motors are standard

or straight cut (fig. 2-8, view A), while the Mk 40 motor

nozzle inserts are scarfed or cut at an angle (fig. 2-8,

view B). The scarfed nozzles used on the Mk 40 motor

impart a stabilizing spin to the rocket when launched at

low initial-launch speeds, such as from helicopters and

low-speed aircraft. A rocket using the Mk 40 motor is

designated a LSFFAR (low-speed, folding-fin, aircraft

rocket) and is used only on helicopters or low-speed

aircraft.

All Mk 16 motors have a single nozzle with four

straight folding fins (fig. 2-9) that attach to the aft end

of the motor tube by threads. To protect the propellant

grain from moisture and to promote propellant grain

ignition, the nozzle opening is closed by a thin metal seal

and a foam plug. A light plastic fin retainer holds the

fins folded within the diameter of the rocket until

propellant ignition. On ignition, the fin retainer is blown

off. Gas pressure exerted on the heels of the fins pushes

the fins open as they emerge from the launcher tube.

The fins are then locked in the flight position by the

spring-loaded pawls.

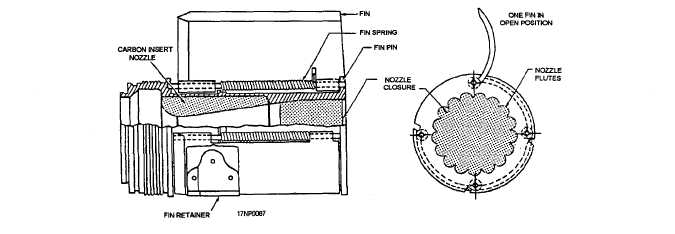

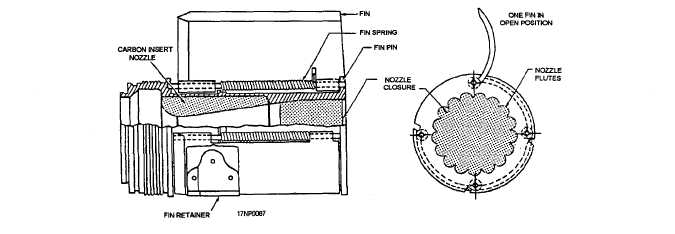

The Mk 16 Mod motor has a modified igniter and a

modified nozzle and fin assembly. The nozzle and fin

assembly (fig. 2-10) contains four, spring-loaded,

wraparound fins inside the motor diameter. The steel

nozzle expansion cone has flutes that cause the rocket

to spin during free flight. This permits the rocket to be

launched from high-speed aircraft, helicopters, and

low-speed aircraft.

Figure 2-10.—Mk 71 Mod 0 motor, nozzle, and fin assembly.

2-7