Motor-Operated Valves

the interior and exterior of the motor clean and free of

dirt. Remember, dirt and debris are the major causes of

motor failure.

Motor-operated valves allow the console operator

TROUBLESHOOTING.-- As a GSE, you must

remote control of certain valves in the ship's service fuel

troubleshoot the fuel booster pump motors whenever

system. Motor operators are found on the fuel service

tank suction and recirculating valves and fuel booster

malfunctions occur. A fault in the motor is usually

pump suction valves.

caused by short circuits, open circuits, or grounds. You

must locate and repair these faults to restore the fuel

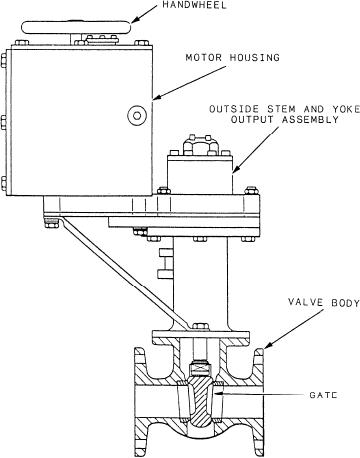

Study the motor-operated valve shown in figure 4-1.

The motor-operated valve assembly consists of an

system to its maximum operating condition. Refer to

electric motor driving a gear drive system that is coupled

chapter 5 for additional information on troubleshooting

to a valve. The motor housing contains a torque limiter

the fuel booster pump motors.

that protects the valve and the motor from overload

damage. Most types of motor-operated valves will also

Fuel Booster Pump Controllers

include a handwheel that permits manual operation if

electrical malfunction occurs. Motor-operated valves on

gas turbine-powered ships are remotely controlled from

On gas turbine-powered ships, the controllers for

the PCC, PACC, PLCC, and SCU, or locally at the valve

the fuel service system are located in the engine rooms.

controller.

The controllers operate from a 3-phase, 60-Hz, 440-volt

ac source and provide local control of the fuel booster

MAINTENANCE.-- The maintenance on motor-

operated valves includes cleaning, inspecting, and

pumps. The pumps can be stopped and started from

testing. The controller of a motor-operated valve is

these controllers. The controllers are usually equipped

nothing more than a simple reversing controller. The

with reset push buttons to restore motor overloads.

maintenance procedures used on motor-operated valves

M A I N T E N A N C E . The maintenance for the

are the same as those you would use to maintain basic

ship's service fuel booster pump controllers is the same

motors and controllers. On most gas turbine-powered

as for any other type of electrical controller. On most

gas turbine-powered ships, you, the GSE, will be

responsible for the maintenance of these controllers. On

some ships, however, this task may be the responsibility

of the electrician's mates (EMs).

In any case, proper preventive maintenance will

reduce the chance of failure in this equipment. Routine

PMS includes keeping the insulation resistance of the

control and power circuits high and making sure the

electrical connections are tight. Any problems you find

in the controllers must be corrected immediately. Make

sure you follow the proper electrical safety precautions

during the maintenance of these controllers.

TROUBLESHOOTING.-- During PMS on the fuel

booster pump controllers, you will sometimes find it

necessary to troubleshoot these devices. A fault in the

controller is usually caused by short circuits, open

c i r c u i t s , or grounds. Since the controller is an

electromechanical device, it will sometimes give in to

mechanical failure. You, the GSE, also must locate and

repair these types of faults to the controller. Refer to

chapter 5 for additional information on troubleshooting

Figure 4-1.--Fuel service system motor-operated valve.

fuel booster pump controllers.

4-2