further removal of moisture. From the scrubber

steam separator/water reservoir to the tube

element, the steam passes through an orifice and

bundle and back to the steam separator. The

enters the dry pipe, which carries it to the steam

pump is capable of recirculating boiler water at

header. The separated water falls to the base of

a rate that exceeds the evaporation rate.

the separator. Vanes in the base of the separator

serve to maintain the rotary motion of the water

until it is discharged from the outer edge of the

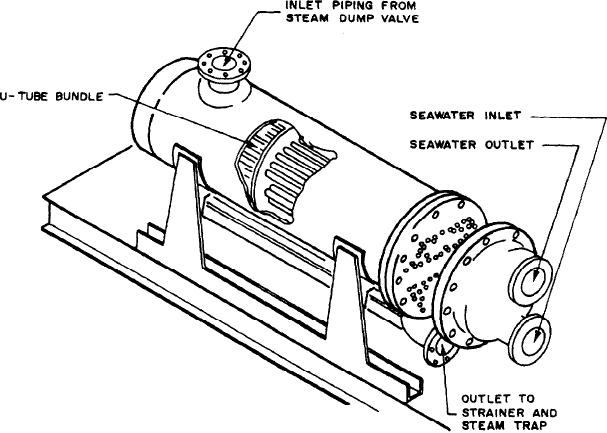

Control Condenser

separator into the reservoir.

Connections are provided on the steam drum

The purpose of the control condenser is to

for high- and low-water level control, feedwater

condense the excess steam resulting from

inlet, boiler-water outlet, and a water level sight

variations of steam demand and exhaust gas

gauge. A manhole provides access for inspection

temperature. The condenser (fig. 7-32) is a

and maintenance. Provision is also made for

shell/tube design with the coolant (seawater)

bottom blowdown and draining. The two safety

flowing through the tubes, It has the capacity to

valves, vertically mounted on the shoulder flanges

condense the total boiler output at all operating

of the steam separator drum, protect against over-

conditions.

pressurization. The valves are identical except for

their pressure settings. Steam discharge from the

safety valves is piped to the exhaust gas outlet

Boiler Control Panel

duct.

The control panel is an integral part of the

Recirculation Pump

waste-heat boiler. It contains the boiler controls,

warning lights, an alarm bell, indicating lights,

The purpose of the recirculating pump is to

and gauges for local monitoring of all boiler

provide a continuous flow of water from the

operating parameters and steam distribution

Figure 7-32.--Control condenser.

7-31