certain arc chutes are securely fastened. Be sure

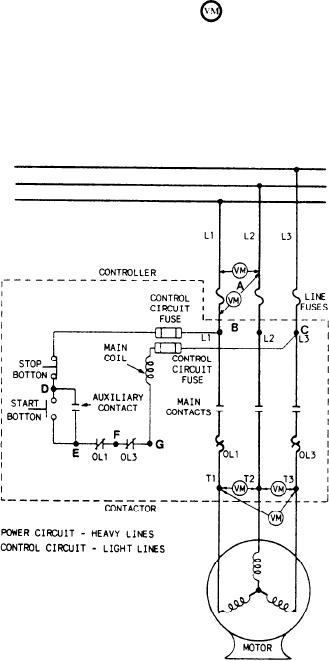

example of troubleshooting a motor-controller

there is enough clearance to prevent interference

electrical system is given in a sequence of steps

when the switch or contact is opened or closed.

that may be used in locating a fault (fig. 10-10).

Replace shunts and flexible connectors, which

We will analyze the power circuit and then the

control circuit.

are flexed by the motion of moving parts, when

worn, broken, or frayed.

Regularly test the CBs by testing them on how

they are intended to function. For manually

POWER CIRCUIT ANALYSIS

operated CBs, simply open and close the breaker

to check the mechanical operation. To check the

When no visual signs of circuit failure can be

mechanical operation and the control wiring, test

located and an electrical failure is indicated in the

electrically operated CBs by the operating switch

power circuit, first check the line voltage and fuses

or control. Exercise care not to disrupt any

(or CB), as shown in figure 10-10. Place the

electric power supply that is vital to the operation

voltmeter probes on the hot side of the line fuses

of the ship. Also, be careful not to endanger

as shown at position A. A line voltage reading

personnel by inadvertently starting motors and

tells you that your voltmeter

is operational. It

energizing equipment under repair.

tells you that you have voltage to the source side

Before returning a CB to service, inspect all

o f the line fuses. Y o u may also check

mechanical and electrical connections. These

between the other lines. To check the fuse in line 1

include mounting bolts and screws, drawout

(L1), place the voltmeter across the line fuse as

disconnect devices, and control wiring. Tighten

where necessary. Give the breaker a final clean-

ing with a cloth or compressed air. Operate

manually to be certain all moving parts function

freely. Check the insulation resistance with a

Megger before reinstalling the CB in the SWBD.

CONTROLLER

TROUBLESHOOTING

Although the Navy maintains a policy of

preventive maintenance, sometimes trouble is

unavoidable. In general, when a controller fails

to operate or signs of trouble (heat, smoke, or

smell of burning) occur, you can find the cause

of the trouble by a simple examination using the

sense of feel, sight, or smell. However, at other

times, finding the trouble involves more detailed

actions.

Troubles tend to gather around mechanical

moving parts. Problems also occur where

electrical systems are interrupted by the making

and breaking of contacts. Center your attention

in these areas.

When a motor-controller system has failed and

pressing the START button will not start the

system, press the overload relay reset push

buttons. Then attempt to start the motor; if the

motor operation is restored, no further checks are

required. However, if you hear the controller

contacts close but the motor fails to start, check

the motor circuit continuity. If the main contacts

don't close, check the control circuit for

Figure

10-10.--Troubleshooting a

3-phase

magnetic

continuity. In the following paragraphs, an

controller.

10-11