RTDs provide for remote readout of each bear-

ing's temperature on the digital demand displays.

Strut Bearings

Each propeller shaft extending aft of the stern

tubes is supported by a strut. Each strut contains

a seawater-lubricated bearing. The strut bearings

are cooled by constant immersion in seawater and

are not monitored by the ECSS.

Stern Tube Bearings

The stern tube bearings are in constant

contact with the seawater surrounding the stern

tubes. The clean seawater that passes through the

stern tube seals from the ship's firemain system

or seawater service system also flows through the

stern tube bearings. They are identical to the strut

bearings in design. However, the strut bearings

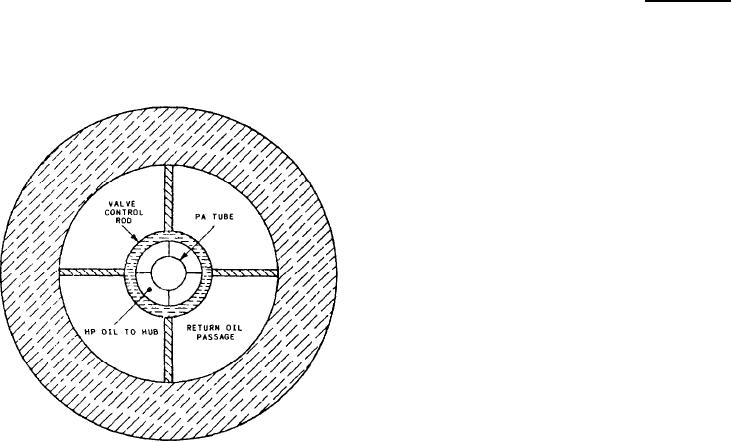

Figure 8-28.--Cross-sectional view of propulsion shaft.

are roughly 5-inches larger in diameter and twice

as long as the stern tube bearings. The stern tube

bearings are not monitored.

space between the valve rod and the inside

diameter of the propulsion shaft. It then flows

through the OD box to the hydraulic oil sump

PROPULSION SHAFT SEALS

tank.

The propulsion shaft penetrates the hull and

various compartment bulkheads. At these points

SHAFT BEARINGS

it is necessary to install some type of sealing

arrangement to prevent progressive flooding

The shaft bearings are used to support the

b e t w e e n compartments. Where the shaft

shaft. Bearings are mounted in the stern tube and

penetrates a compartment bulkhead, they are

propeller strut and are seawater lubricated. The

naturally called bulkhead seals. Where the shaft

remaining bearings are self-aligning, oil-lubricated

penetrates the hull, they are called stern tube seals.

journal bearings commonly called line shaft bear-

ings (LSBs). Each LSB is a self-contained

assembly with its own oil reservoir that contains

Bulkhead Seals

2190 TEP oil.

The bulkhead seals will maintain watertight

An oil disc clamped to the shaft is used in each

integrity of the bulkhead penetrated by shafting

when either side of the bulkhead is flooded. These

bearing to deliver oil to the upper bearing and

seals are self-aligned with the shaft. They will

journal surfaces. As the disc rotates, it picks up

oil from the bearing reservoir and carries it to the

accommodate 1.75 inches perpendicular move-

ment of the shaft with longitudinal movement of

oil scraper on the upper shell. The scraper removes

0.040 inches because of thrust bearing clearance

oil from the disc and directs it to the upper bear-

and 0.50 inch because of thermal changes.

ing lining. A clear sight hole cover on the bear-

ing housing allows visual confirmation of the oil

The seal assembly consists of a base

level and oil disc operation.

ring bolted to the bulkhead, two sealing

discs, right-hand and left-hand sealing rings,

and a cover. The two sealing rings are identical,

All bearing pedestals have an oil level rod and

except that one is a mirror image of the

an oil reservoir thermometer for checking oil level

other. They are formed by three plain and

and temperature. An RTD is installed in the lower

bearing shell of each oil-lubricated bearing. The

three slotted carbon segments. Six pressure ring

8-45