segments (fig. 8-29) are placed around the two

of water pressure, so flooding is confined to the

carbon sealing rings, and the assembly is held in

one compartment only.

place by two garter springs. The two sealing discs

are installed with one on either side of the seal-

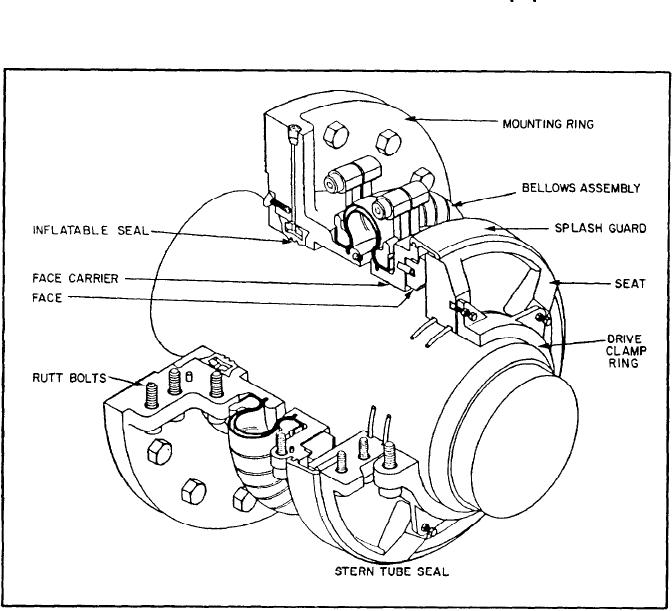

Stern Tube Seals

ing rings. Attached to each sealing disc are three

stops that mate with the slotted carbon segments.

The purpose of the stern tube seals is to pre-

These stops ensure that the sealing ring assembly

vent seawater from entering the ship at the point

does not rotate with the shaft.

where the shaft or shafts penetrate the hull.

Different types of stern tube seals are installed

When the compartment on one side of the seal

aboard ships, but they all serve the same purpose.

is flooded, water pressure on the carbon sealing

We will use the MX9 model installed on the

ring on the wet side creates a gap between the

DD-963 class ships as an example of a stern tube

carbon ring and sealing disc. This gap allows

seal.

water to enter the seal housing to force the other

The MX9 seal (fig. 8-30) is a radial face,

sealing ring against the shaft and sealing disc.

hydraulically balanced seal located on the inboard

Pressure on the far side sealing ring is directly

side of the ship's stern tube. Primary sealing

proportional to the head of water in the flooded

occurs between the stationary face insert and the

compartment plus the contact pressure of the

rotating seat in a plane perpendicular to the center

garter spring. Sealing action is a direct function

line of the shaft.

Figure 8-30.--MX9 stern tube seal.

8-47