mounted on the gear case transmits clutch status

SYNCHRO-SELF-SHIFTING CLUTCH

as ENGAGED/DISENGAGED to the control

consoles. A hydraulic locking feature is provided

Identical positive drive SSS clutches connect

in the design to prevent inadvertent clutch

the GTEs to the MRG power train. Each clutch

disengagement during normal transient or shock

is supported by the input shaft and the HS pinion

conditions. A local visual indicator indicates

couplings. The clutches permit operation with

clutch status (ENGAGED or DISENGAGED).

either one or both GTEs driving the propeller.

They also permit changing GTE combinations

Two microswitches (situated in pairs for double-

while the MRG continues to rotate. The clutches

pole changeover action) are provided in each

clutch to give remote indication of these positions.

are fully automatic, free-wheeling devices. They

The clutch is lubricated from an oil supply shaft

transmit torque (power) through splines and gear

teeth machined in the clutch elements without

mounted in the HS pinion bore.

external controls. Clutch engagement is initiated

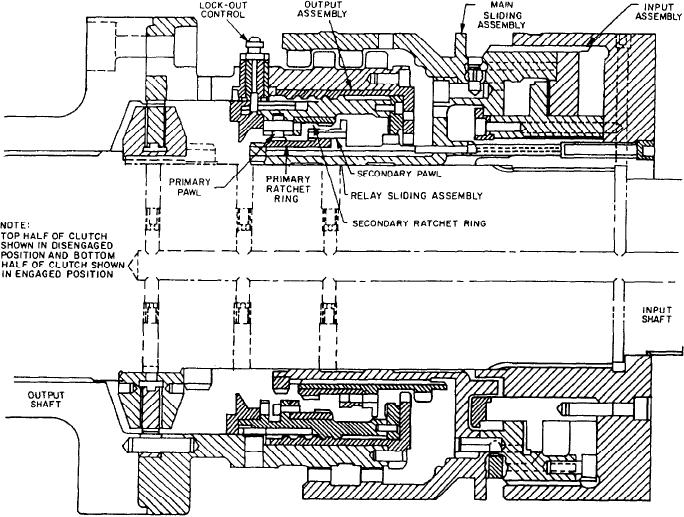

The SSS clutch has an input assembly, a main

by a pawl and ratchet mechanism.

sliding assembly, a relay sliding assembly,

and an output assembly. Figure 8-8 is a

Figure 8-7 shows a clutch assembly. A

cross-sectional view of the clutch showing

manually operated lockout device prevents clutch

the primary components. The clutch also has a

engagement when actuated. The associated GTE

status indicator switch mechanism not indicated

can then be operated independently of the rest of

in figure 8-8.

the power train. An indicator/switch unit

Figure 8-8.--SSS clutch (primary components).

8-11