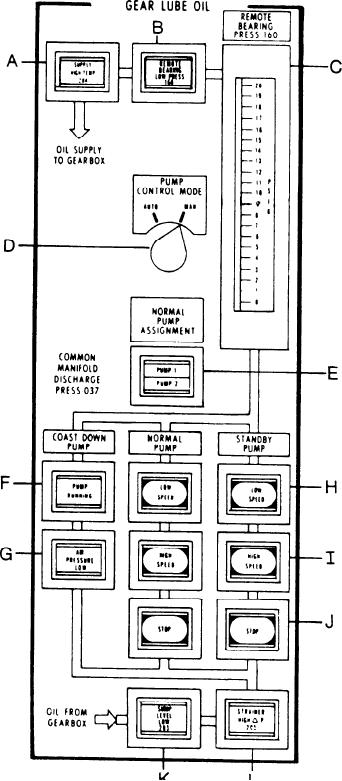

two-position switch (D) labeled PUMP CON-

TROL MODE is used to select either the AUTO

or MAN (manual) control mode. The next split-

legend indicator (E) labeled PUMP 1 and PUMP

2 illuminates to indicate which pump is assigned

the NORMAL position. Normal and standby

pump assignment is done by a switch on the LO

pump controller in the engine room.

If the LO pressure drops to 9 psig, or if both

electric pumps lose power, a third air-driven pump

provides oil to the MRG. This pump is called a

COAST DOWN PUMP. It has an indicator (F)

labeled PUMP RUNNING on the PCC to show

when it is running. The coastdown pump will only

run if the shaft is turning. Also, it will stop if the

LO pressure exceeds 15 psig. The next indicator

down (G) is labeled AIR PRESSURE LOW. It

illuminates and sounds an alarm to alert the

operator when the air supply to the coastdown

pump is low. It activates at 2700 psig.

The speed control push buttons are used for

manual speed control of the electric LO pumps.

They are labeled LOW SPEED (H), HIGH

SPEED (I), and STOP (J). They will illuminate

to indicate the status of the pump(s). The operator

may use these push buttons in the manual mode

to STOP, run in HIGH SPEED, or run in LOW

SPEED the normal or standby LO pumps. First,

the NORMAL PUMP is selected (its selection is

shown by the NORMAL PUMP ASSIGNMENT

PUMP 1/PUMP 2 indicator (E)). Then, the

operator manually starts the selected pump to start

the LO system. After the LO system is started,

the operator may put the system in automatic by

placing the PUMP CONTROL MODE switch (D)

to AUTO. In the AUTO mode, the pumps cycle

up in speed in response to pressure decreases. If

the pressure drops to 15 psig, the NORMAL

PUMP shifts from LOW SPEED to HIGH

SPEED. A drop in pressure to 13 psig causes the

STANDBY PUMP to start in LOW SPEED. A

further decrease in pressure to 11 psig causes the

standby pump to go to HIGH SPEED. When

system pressure returns, the pumps must be

Figure 6-9.--Gear lube oil panel.

manually cycled to lower speeds or off.

BEARING LOW PRESS illuminates and an

The next indicator (K) labeled SUMP LEVEL

alarm sounds. The operator can monitor the LO

LOW, alerts the operator when the level of the

pressure at the PCC by using the hydraulically

MRG oil sump drops below 870 gallons. The

most remote bearing pressure on the meter (C)

indicator (L) next to SUMP LEVEL LOW is the

labeled REMOTE BEARING PRESS.

STRAINER HIGH AP. If the differential pressure

Control is available from the PCC for the two

across the LO strainer exceeds 12 psid, this

motor-driven, two-speed pumps. The rotary

indicator illuminates and an alarm sounds.

6-17