across the current transformers. This signal

represents the kilowatt load on the generator's

individual phase windings. At 1,000 kW, the

circuit is armed for high transient loads. With a

500-kW step increase, however, the sensor will

transmit a signal to close the turbine's 14-th

stage bleed air valve. This action of the sensor

will prevent engine stalls resulting from such

load variations.

The transient load sensor also monitors the

generator's main circuit breaker and its

shutdown relays. Consequently, other SSGTGs

on the bus will receive a bleed valve closure

signal if a shutdown should occur.

Hand Pump Assembly

Study figure 7-1 and focus your attention on

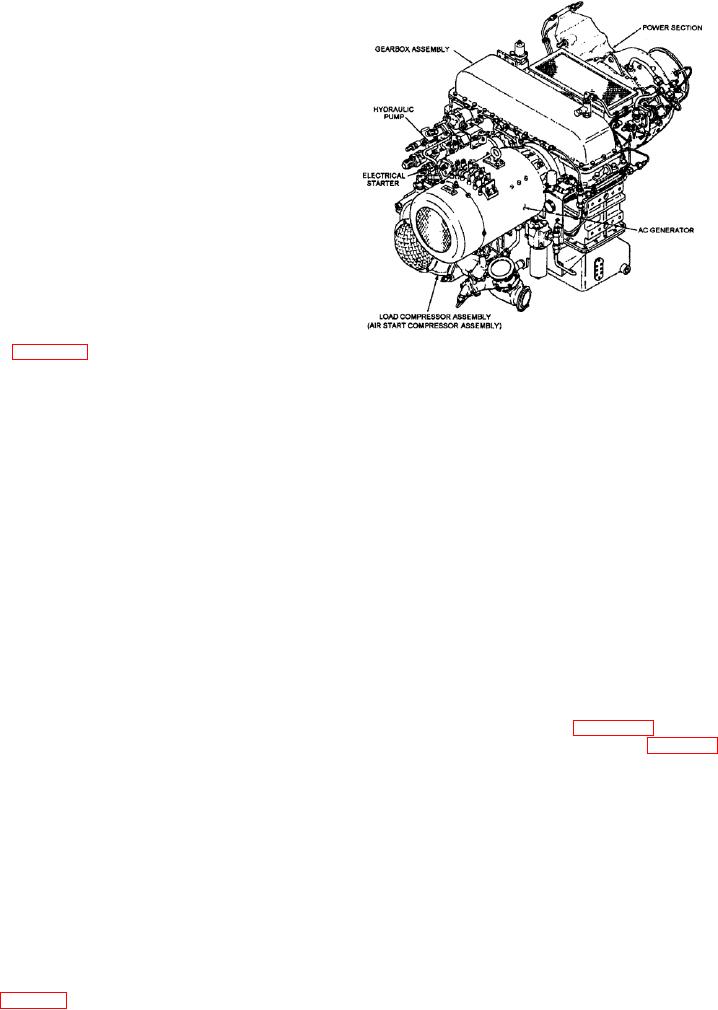

Figure 7-5.Garrett ship's service power unit

the space between the generator and the

(SSPU).

enclosure. On the Allison 501-K34, a new piece

of equipment, a hand pump-operated actuator

mounted on the module's exterior wall, has been

CONSTRUCTION AND DESIGN

added. The pump is used to close the fire damper

if ship's service air or power is not available.

The electric plant of the Garrett ME 031-800A

SSPU includes the following five systems:

Because of this new item, a change was

made to the K34's start air piping. The change

1. Electrical system

on the K34 provides a single manifold where the

high-pressure and low-pressure start air enter

2. Lubrication system

the starter inlet. In the older Allison model, the

3. Fuel system

high-pressure and low-pressure start air were

individually piped to the starter.

4. Water wash system

Now that we have discussed the important

5. Bleed air (de-icing) system

design differences in the Allison 501-K17 and

K34 models, let's take a look at the prime mover

Before we look at each of these systems and how they

used on the PHM-class ships, the Garrett ME

work, let's first describe the SSPU in terms of its two

831-800A.

major sections: (1) the power section and (2) the

gearbox assembly section. Figure 7-5 shows an

orthographic view of the SSPU. Refer to figure 7-5 as

GARRETT ME 831-800A

we describe the construction and design features of

both sections.

Manufactured by the Garrett Corporation,

the ME 831-800A ship's service power unit

The power section consists of the 2-stage

(SSPU) is the electrical and hydraulic power

centrifugal-flow compressor, the 3-stage axial-flow

source on the PHM-class ships. On these

turbine, the inlet plenum, and the combustion

hydrofoils, the SSPU provides the electrical

system. The power turbine is mounted on the rear of

power to (1) activate the compressed air system

the gearbox assembly.

that starts the foil borne engine, (2) drive the ac

generator, (3) support the speed and load control

The gearbox section consists of the reduction

circuitry and equipment, and (4) operate the two

gear train contained in a split-housing assembly.

hydraulic pumps.

Mounted on the reduction gear assembly are the ac

generator, two hydraulic pumps, and a load

compressor. A more detailed description of the

In chapter 6, we gave you an overview of

gearbox and its operations will be provided later in

this SSPU. Now, let's take a slightly closer look

this chapter.

at some of its systems and components.