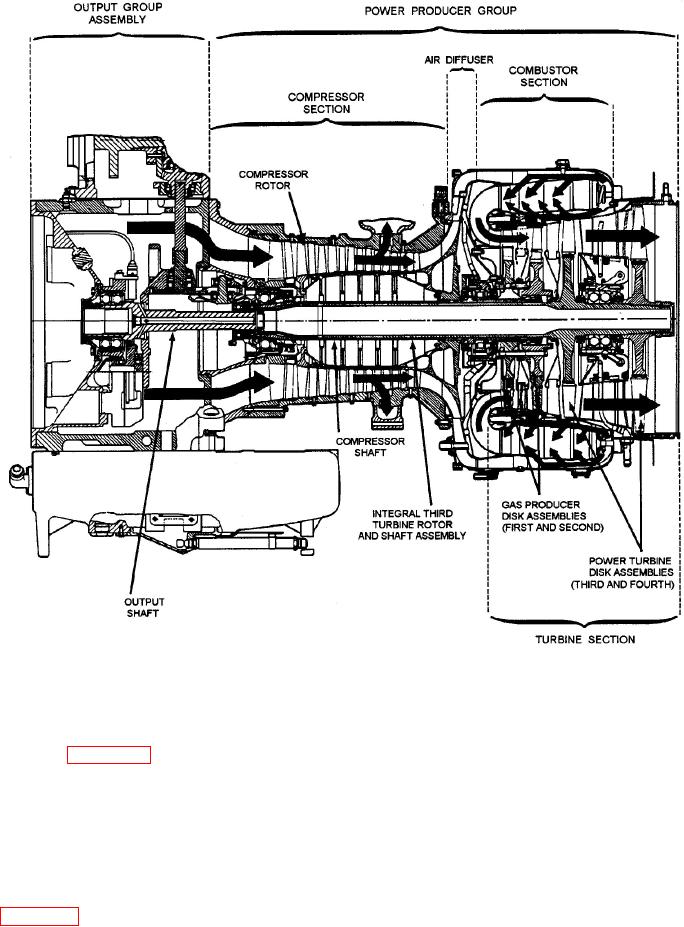

Figure 6-3.-Operation and primary airflow of TF40B gas turbine engine (LCAC).

compressor shaft, is splined to the power output shaft

Components and Assemblies

assembly. The power output shaft assembly is located

at the forward end of the engine. Its speed is equal to

As you study figure 6-2, notice how the TF40B is

power turbine speed. Externally, the power output

basically composed of two major sections: (1) the

group assembly provides mounting pads for several

output group assembly and (2) the power producer

accessories and components required for engine

group. The power producer group includes the gas

operation.

producer module and the combustor and the power

turbine assembly. The output group assembly

Notice how the two major sections of the TF40B

includes the accessory gearbox module, inlet housing

are structurally interdependent. Working together as

module, and sump module. The power producer group

an operating unit, they provide an annular flow path

provides a reverse annular flow path for air and hot

for the air or hot gases, support internal rotating

gases. (See fig. 6-3.) The compressor rotor assembly is

systems, and provide external attaching capabilities

directly connected to the first and second gas

for components and accessories required for engine

producer disk assemblies. The fourth turbine rotor

operation. An important advantage of this design is

disk assembly is directly connected to the power

that it allows for the removal and installation of

turbine integral third turbine wheel disk shaft

engine modules. This

assembly. This assembly, which runs inside of the