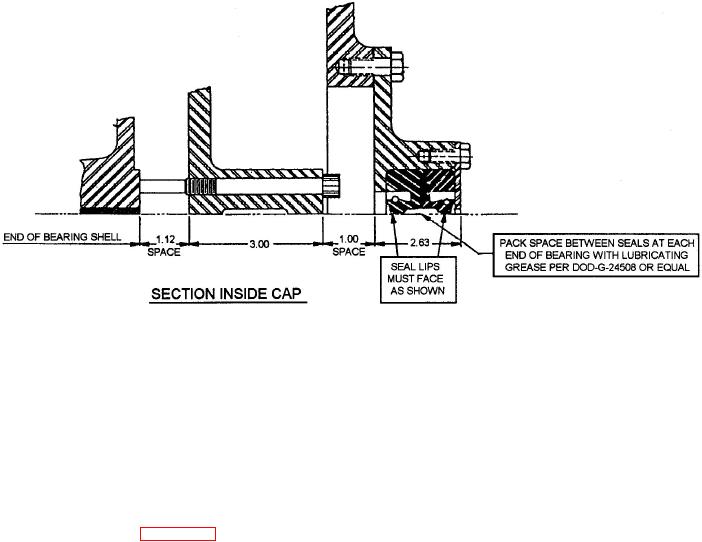

Figure 5-7.-Cross-sectional view of LSB oil seals.

procedures provided in the manufacturer's technical

The procedure for seal installation is usually

manual.

included in the package containing the seal. If the

instruction sheet is missing, you can find the

MAIN THRUST BEARING. Even though seal

installment procedure in the NAVSEA technical

manual for the model of the line shaft bearing

replacement can be and has been accomplished by

installed on your ship. A couple of key points for you

ship's force personnel, many engineer officers prefer

to remember are (1) make sure you use only an

to have an outside activity make the repair. The

approved adhesive to join the butt ends of the seal

reason for this is because the bearing cap must be

together and that you pack the space between the two

removed. It is extremely heavy and awkward. Few

seal faces as described in figure 5-7, and (2) make

ships have the necessary rigging experience to handle

sure you properly space the seal split lines.

this piece.

BULKHEAD SEAL. The bulkhead seal is

Removing the bearing cap is very dangerous. The

cap must be properly rigged for lifting. If, because of

another component that can easily be maintained by

limited space, it cannot be moved clear of the working

ship's force personnel. Because the bulkhead seal

area, it could possibly be left hanging directly over

does not support the shaft, virtually every part of the

your head while you arc working on the seal. Because

seal assembly can be removed and replaced without

of these potential safety hazards, make sure all

disturbing the shaft alignment. Normal wear and

precautions and instructions are followed to the

tear will require periodic replacement of the sealing

letter.

rings and garter springs. Sometimes, as the result of

an inspection, the replacement of the compression

SUMMARY

springs or the sealing discs may be necessary. One

key point to remember: Always handle the sealing

In this chapter, we have provided you with an

rings with care. These rings are made of carbon and

overview of the propulsion plants systems and drive

they can be damaged or broken easily.

train equipment and systems used on gas turbine-

powered ships. We discussed some ways in which you

STERN TUBE SEAL. The replacement of the

can properly operate and use your ship's propulsion

stern tube seal assembly can be accomplished by the

plant. If you properly maintain your propulsion plant

ship's force if the ship has all the tools required to

and its equipment, the plant will provide your ship

perform the job. The person assigned to perform this

with a high level of efficient service. With the

procedure must be experienced. Because a seal must

information provided in this chapter and the

be placed around the shaft at the hull penetration

recommended technical publications, you should

point, a qualified diver is necessary. Once all of these

become a more effective gas turbine systems

precautions are taken, seal replacement can

technician.

commence. Always, you should carefully follow the