Figure 5-5.-Depth micrometer readings.

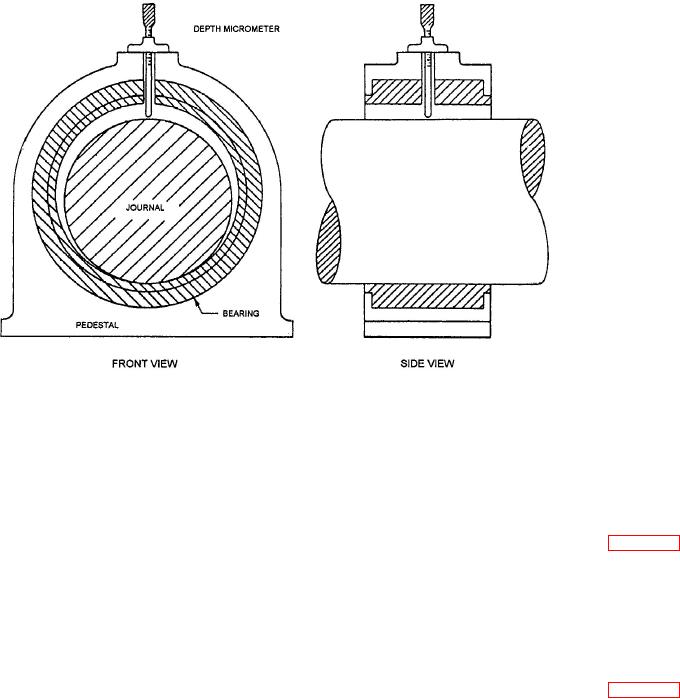

surface must be kept clean and free of nicks so

MAIN THRUST BEARING. The main thrust

correct depth readings can be taken.

bearing does not require any special cleaning. Its

cleaning is usually performed as part of the MRG

2. A depth constant (installation reading) is

cleaning. You should follow the cleaning tips we

inscribed on or near this flat surface. You

described earlier for the components of the MRG.

must use this reading every time you perform

a depth measurement, as shown in figure 5-5.

Inspections and Tests

You must make sure you give the same care to

acquiring depth micrometer readings as you

Most of the tests and inspections we will discuss

would give to the measuring flat surface.

are accomplished according to the PMS. Because of

casualties, however, you may be required to

BULKHEAD SEALS. You will usually inspect

participate in some unscheduled inspections. We will

the bulkhead seals at the same time you clean them.

now discuss some of the most common tests and

This inspection will require the complete disassembly

inspections performed on the components we just

of the seal to expose those parts shown in figure 5-6.

discussed in the preceding paragraphs.

Once the seal cover is removed, pay particular

attention to the condition of the compression and

LINE SHAFT BEARINGS. The task you will

garter springs and the surfaces of the two

perform the most frequently on the line shaft bearing

(segmented) carbon sealing rings. These springs

(LSB) will be a visual inspection while the propulsion

should not be cracked or distorted. The sealing rings

shaft is in operation. You should perform this

must have an even wear pattern and should be free of

inspection once an hour to check for proper oil flow,

nicks and scratches. An uneven wear pattern on the

oil temperature, and leaking seals and covers.

face of the sealing rings is an indication of improper

garter or compression spring pressure or possibly the

The other inspection that you as a technician

binding of a ring segment. Remember, the condition

could be required to perform will be a bearing wear

of a sealing ring is only as good as the condition of the

measurement. This procedure is covered under the

journal surface on the propulsion shaft.

PMS, but here are some important tips you should

remember:

You should also inspect the surfaces of the two

sealing discs to make sure the discs have not slipped

1. All of the line shaft bearings installed on gas

from their correct position. (Remember, these discs

turbine ships have a machined flat surface and

are stationary.) Scoring on the sealing surface of

a removable plug for micrometer access on the

either

top of the upper bearing shell cap. This flat