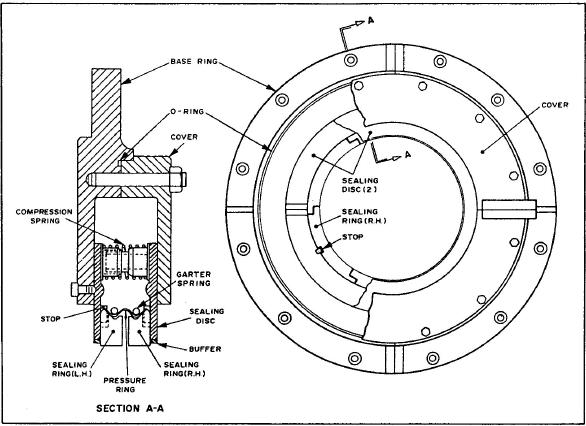

Figure 5-6.-Cutaway view of a typical bulkhead seal.

required air pressure. Next, you should check the

sealing disc is a good indication that you have a few

seawater cooling system. Check both the ship's

weak compression springs that have allowed the disc

seawater cooling system, which provides cooling

to rotate with the shaft.

seawater during normal operations, and the firemain

system, which provides emergency cooling seawater,

Another key point to look for is signs of wear on

for proper pressure and flow. If a seawater strainer is

the buffers installed on the bottom of the sealing

included in your ship's seawater cooling system,

discs. If you detect wear and the pattern of wear is

check it also and clean it as required. Then, you

not uniform, then the shaft to bulkhead seal

should check the stem tube seal itself for leakage.

alignment is most likely incorrect.

Even though the sealing assembly is mechanical, you

can adjust the spring pressure to maintain a proper

STERN TUBE SEALS. Your inspection of an

seal. We will explain this adjustment procedure later

individual stem tube seal should consist of the seal

in this chapter.

and its support systems. There are two support

systems you should check: (1) the seawater service

MAIN THRUST BEARING. The main thrust

system, which provides cooling; and (2) the ship's

bearing will normally be inspected as frequently as

service air system, which provides the air for seal

the MRG when the propulsion plant is in operation.

inflation.

During a normal inspection, you should check for the

proper oil flow and oil temperature and for leakage.

You should check both subsystems for proper

You should also periodically inspect the main thrust

operation as they pertain to the operation of the stern

bearing according to the PMS for excessive thrust.

tube seals. For example, you should check the

Like the LSB, you should use a depth micrometer to

inflatable seal operation at least every 6 months.

measure the thrust. Normally, the measurement plug

Remember, the proper operation of the inflatable seal

is located on the propulsion shaft side of the MRG

is crucial to safety and your ship's ability to survive.

casing. By moving the shaft first in the ahead and

Check both the ship's service air system, which

then in the astern direction, you can measure the

provides air pressure under normal operation

actual movement of the second reduction gear (bull

conditions, and the compressed air bottles, which

gear). Use these readings in the same reamer as you

supply emergency air pressure to the seals, to make

would the thrust readings for a LSB.

certain the inflatable seal is always supplied with the