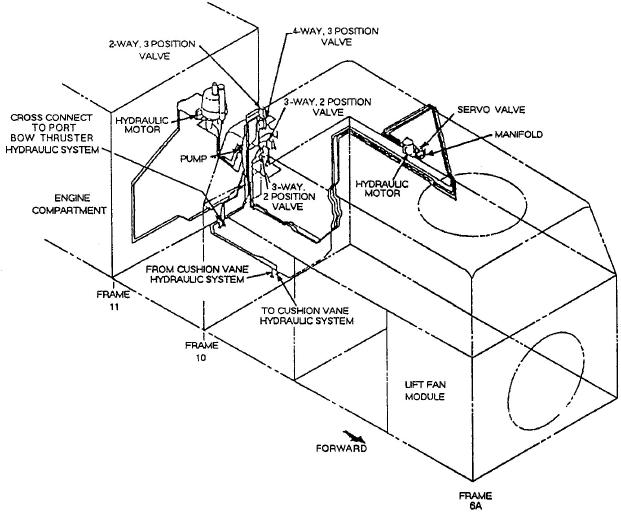

Figure 6-8.-Physical arrangement of the LCAC bow thruster control system.

switch, labeled RUDDER A/B, allows the operator to

control components. The operator can use either

choose between channels of the CSEP in case of an

CSEP A or CSEP B to route a rudder control signal.

emergency or system fault.

RUDDER POSITION DRIVE ASSEMBLY.

RUDDER

CONTROL

SYSTEM

The rudder position drive assembly contains a valve

coil, hydraulic drive servomotor, and feedback

INDICATORS. Indicators are provided on the

potentiometer. The CSEP sends an electrical drive

alarm and monitor system (AMS) cathode ray tube

signal to the electric drive servomotor through the

(CRT) display monitor, The display monitor is located

valve coil to position the rudders. As the rudders are

at the engineer control station. The indicators include

positioned, a feedback signal goes to the CSEP. When

the following:

the feedback signal is equal and opposite to the drive

signal, the rudders are in the desired position.

Rudder control failure

RUDDER BLADES. The craft's two rudders arc

Port and starboard hydraulic reservoir low

mounted vertically across the trailing edge of each

propeller shroud. The rudder blades are broad, flat,

Port and starboard hydraulic pressure low

aerodynamic, movable devices that measure 10.4 feet

long and 2.3 feet wide. The rudder blades allow the

Bow Thruster Control System

operator to maneuver the craft by deflecting the

propeller slipstream at various angles.

The purpose of the bow thruster control system is

to allow the operator to turn the bow of the craft and

RUDDER CHANNEL SELECTOR SWITCH.

to move the craft in close places. This system is

The rudder channel selector switch is located on the

extremely useful when the operator must dock and

command and control (C&C) keyboard at the

undock the LCAC in the dry well of the support ship

engineer station. This