is proportional to the return of normal SSPU speed.

Once the oil pressure is equalized, the buffer spring

force recenters the buffer piston.

Now, picture the operation of all the mechanical

section components in reverse. As the SSPU load

decreases, the flyweights begin to move outward,

causing the governor pilot valve to rise. The oil on the

left side of the buffer piston drains to the oil sump,

thereby causing both the loading piston and the

power piston to move down. Once the fuel

requirement is met, movement of both the loading

piston and the power piston will stop, and the

governor pilot valve will recenter.

Speed Droop Function. The speed droop

function divides and balances loads between the

SSPUs. The speed droop function is automatic when

both generators are operating in parallel and driving

a common load.

The governor power piston, through linkages,

creates the speed droop function. The linkage

mechanism varies the speeder spring loads. The

linkage assembly has an adjustable pin that is

integral with the speed droop bracket. (See fig. 7-12.)

Any movement of the power piston will cause a

change in the position of the adjustable pin. The

changed position of the adjustable pin, in turn, will

determine the change in speeder spring force. No

change occurs when the speed adjustment lever pivot

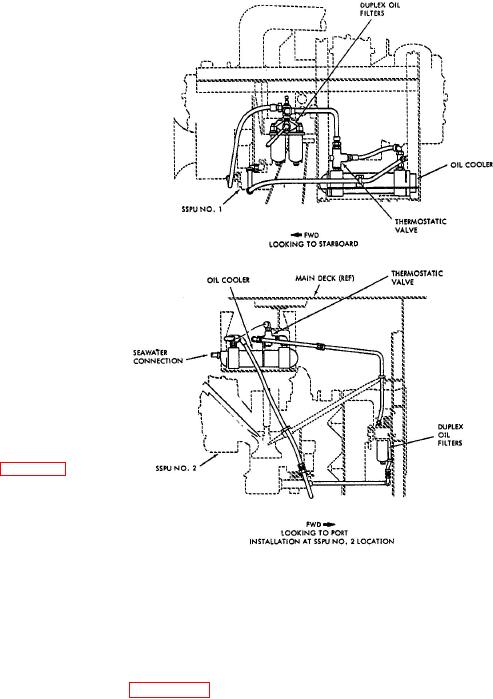

Figure 7-13.Oil cooler, duplex oil filter, and

pin and the adjustable pin are on the same center

thermostatic valve installation.

line. As the adjustable pin moves from the center line,

however, the speeder spring force will change

accordingly.

Cooling for the Garrett's lube oil is provided by a

During electric governor control, the power

seawater type of oil cooler, such as the one shown in

piston will be in the maximum fuel flow position. This

figure 7-13. The cooler is equipped with a

position will be maintained throughout all load

thermostatic bypass valve.

conditions. Therefore, the speed droop function will

be inoperative during electric governor control.

The Garrett's lubrication system is composed of

During governor actuator control, the speed droop

the following major units:

linkage will not alter the speeder spring force.

Oil pump

LUBRICATION SYSTEM

Oil filter assembly

Oil inlet (filter) screen

The lubrication system for the Garrett ME-

831-800A is a full pressure, wet sump type. This

Oil manifold assembly

system provides lubricating oil to the SSPU

bearings, gear meshes, and shafts. It also

Oil cooler

provides lubrication to the ac generator and the

Thermostatic valve

load compressor.

Gearbox vent valve

The capacity of this oil system is 7.8 gallons.

The lower part of the gearbox forms the oil

Duplex oil filter assembly

sump, which is equipped with a filler cap and

Oil sample valve

dipstick for servicing.