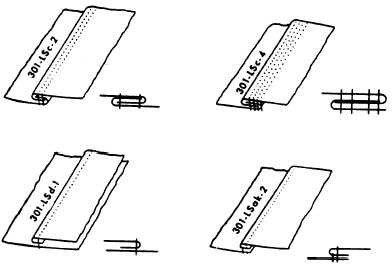

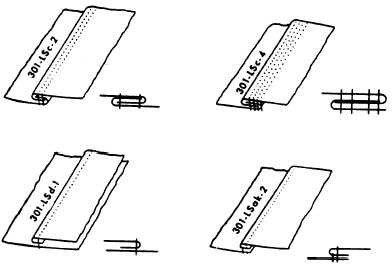

Figure 10-34.—Lapped seam.

2. The LSd-1 seam, as shown in figure 10-34,

is used in sewing pockets or patches. Also, use

the seam to patch small holes.

3. The LSak-2 seam, as shown in figure 10-34,

is used for finishing seams of covers for shop

equipment.

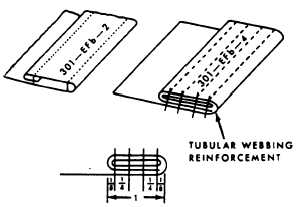

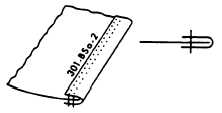

Class BS, Bound Seams.— BSa-2 seams are

made by folding binding strips or tapes over the

edges of the material to reinforce and finish the

edges. Use the BSa-2 seam, as shown in figure

10-35, to bind the edges of tool aprons,

reinforcement panels etc. Most soundproofing is

bound with 3/4-inch tape using the BSa-2 seam.

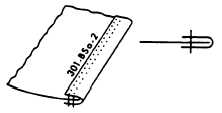

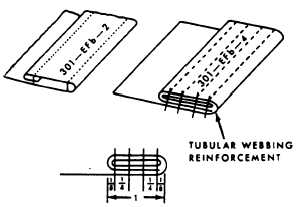

CLASS OF STITCHING.— You form class

EF (edge finishing) stitching by using the edge of

a single ply of material to make the hem. The

EFb-4 stitching, as shown in figure 10-36, is made

by folding the edge back twice, thus turning the

cut edge inside the second fold to prevent fraying

and to reinforce the hem. The hem may also

include a piece of reinforcing tape, plain or

tubular webbing for adding strength. All seams

Figure 10-35.—Bound seam.

Figure 10-36.—Edge finishing stitching.

and stitches pictured are used in the survival

equipment shop for modification and repair work

on the parachute canopy, pack, seat, and back

pads, or for making covers and bags for aircraft,

shop equipment, and tools.

Appropriate Spacing of

Machine-sewn Seams

The following rules will help you to space

correctly more than one line of stitching and to

place a seam the correct distance from the edge:

1. Sew regular binding tape one-sixteenth of

an inch from the selvage edge of the tape.

2. Sew heavier tapes from one-sixteenth to

one-eighth inch from the edge. Sew the raw ends

of the tapes one-fourth inch from the raw edge.

10-27