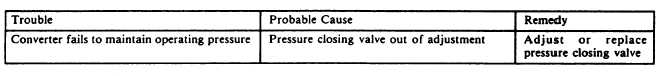

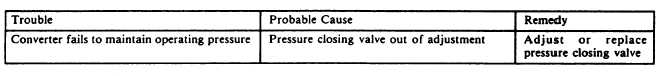

Table 12-23.-Troubkshooting (Flow Test)

8. Remove the fill valve adapter you installed

in step 1.

FLOW TEST

To perform the flow test, proceed as follows:

1. Secure the converter in the rack on the test

stand countertop.

2. Using the Test Stand Hose Assembly, P/N

59A120-B5-12,

connect

the

test

stand

FLOWMETER CONNECTION, NIP-4, to the

CONVERTER SUPPLY OUTLET CONNEC-

TION, NIP-5.

3. Using the Test Stand Hose Assembly, P/N

59A120-B5-47, connect the test stand SUPPLY

TO CONVERTER CONNECTION, NIP-6, to

the converter quick-disconnect coupling.

4. Place the test stand FLOWMETER

SELECTOR valve V-1 in the 0-150 1pm position.

Open the TEST PRESSURE GAUGE BUILDUP

AND FLOW valve V-10. You should not have

a reading of over 70 psig on the test pressure gauge

PG-1. If the test pressure gauge reads over 70 psig,

vent the converter system pressure to 70 psig (refer

to NAVAIR 13-1-6.4).

5. Open the test stand CONVERTER SUP-

PLY FLOW CONTROL valve, V-9, to give a

flow of 120 1pm as indicated on the

FLOWMETER INDICATOR gauge, PG-2.

Maintain the flow for a minimum of 15 minutes.

6. While maintaining a 120 1pm flow, the

converter should maintain pressures of 55 to 90

psig as indicated on the TEST PRESSURE gauge,

PG-1. Record the high and low pressures in the

indicated blocks in section 10 of the Performance

Test Sheet.

7. If the converter supply pressure is not

within limits, locate probable cause using the

troubleshooting chart (table 12-23).

8. Continue flowing the converter until it is

completely empty of LOX. Any means of

evacuating LOX from the converter is acceptable,

provided all safety precautions are followed.

9. Disconnect the test stand hose assemblies,

which you attached in steps 2 and 3. Close all test

stand valves.

CONVERTER CHARGE

Upon completion of the bench test, the

converter is charged with gaseous oxygen to 25

to 30 psig to prevent entry of moisture and other

contaminants during shipment/storage. To charge

the converter, proceed as follows:

1. Secure the converter in the rack on the test

stand countertop, unless it is already there.

2. Using the Test Stand Hose Assembly, P/N

59A120-B547, connect the test stand BELL JAR

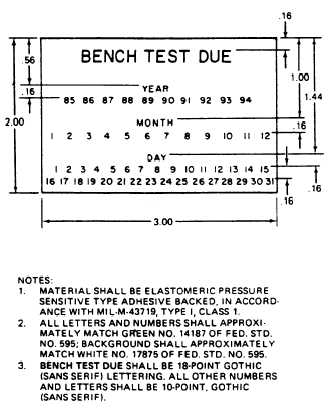

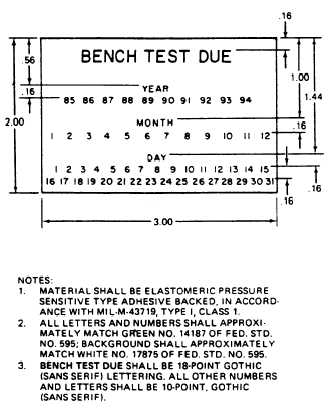

Figure 12-19.—Bench test decal.

12-32