in the feed dog with a distance of 17/32 inch

between the needle bar and the presser bar.

In centering the feeding action, the following

sequence should be followed: Hold the needle

centered in the feed dog with a 17/32-inchspace

between the needle bar and presser bar. Tighten

the feed driving crank and feed driving rockshaft

crank pinch screws, making sure that the crank

is flush with the end of the feed driving rockshaft

and parallel with the bed. Next, tighten the needle

bar rock frame rockshaft crank pinch screw in the

back of the uprise. The shank of the presser foot

is 17/32 inch wide and may be used for measuring

the space.

The next step is to set the sewing hook to or

from the needle. This is done by moving the hook

saddle left or right as necessary; the hook should

pass the needle as closely as possible without

touching. When this is done, retighten the hook

saddle screws. Next, set the sewing hook with the

needle. With the needle bar on the upstroke, the

lower timing mark on the needle bar should be

just visible at the base of the needle bar rock

frame. Set the point of the sewing hook in the

center of the needle 1/16 inch above the eye. To

advance the sewing hook, move the hook drive

gear to the right; and to retard, move the hook

drive gear to the left.

NOTE: The first screw in the hook pinion

gear and the second screw in the hook

drive gear are splined screws. The hook

drive gear must be centered in relation to

the sewing hook shaft at the bottom of the

hook saddle. “

Lubrication of The Class 111

Sewing Machines

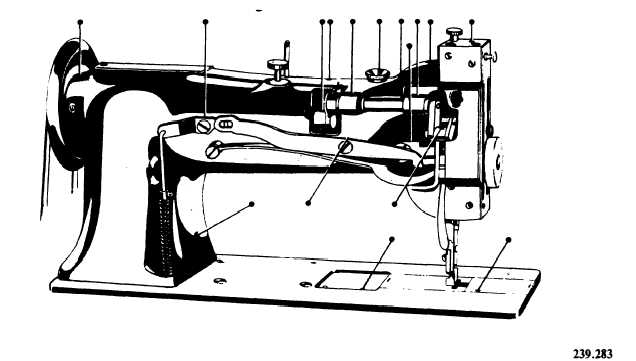

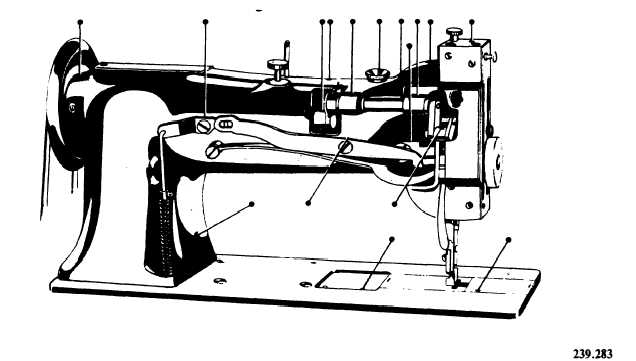

Figures 9-24A, 9-25B, and 9-26 show the

various lubrication points on class 111 sewing

machines. Oiling points are indicated by the

unnumbered arrows. Familiarization with the

nomenclature of the machines may also be

accomplished by studying these illustrations.

To lubricate the class 111 machine, swing back

the top cover and oil the bearings, then replace

the cover.

Loosen the thumbscrew in the upper end of

the faceplate, turn the faceplate upward, and oil

the wick and bearings, as shown in figure 9-25B.

After oiling, turn down the faceplate and tighten

the thumbscrew.

Turn the machine back on its hinges and apply

oil at the places designated by the arrows in figure

9-27. All contacting parts on the bottomside of

the machine should also be oiled.

To lubricate the hook, remove the bed slide

and place oil in the oil well (fig. 9-26). This

Figure 9-26.—Rear of machine, showing oiling points.

9-22