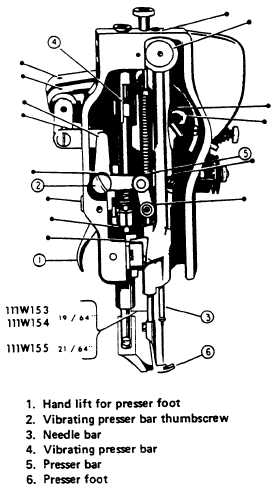

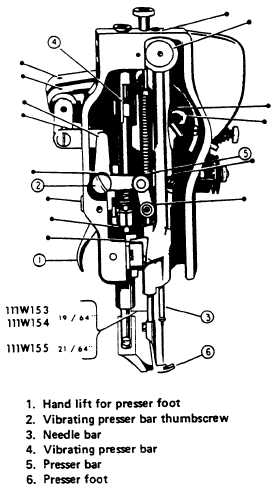

Vibrating Presser Foot. Holds the material

in place while the alternating presser foot rises to

239.282

Figure 9-25B.—Class 111 sewing machine, side view

showing oiling points.

Needle Thread Lubricator. Lubrication of

the thread when sewing leather. Lubrication of

the thread prevents it from fraying, and prevents

the needle from becoming hot when sewing at high

speed.

Needle Thread Tension. Regulates the

tension on the needle thread so that the lockstitch

may be adjusted properly.

Needle Thread Controller Spring As-

sembly. Removes sufficient slack from the

needle thread when the needle is descend-

ing to prevent the needle from splitting the

thread.

Needle Bar. Holds the needle and carries

the thread to the rotary hook where the lockstitch

is formed.

make another stitch.

Lifting Presser Foot. Holds the material

in place while the vibrating presser foot and feed

dog go forward to get material for the next stitch.

The class 111 machine is a compound feed

machine. This means that the feed dog, vibrating

presser foot, and needle move together to feed the

material. Some class 111 machines are equipped

with a compound feed only, such as the 111 W

151; and others are equipped with a combination

of the compound feed and alternating presser foot

that holds the material while the needle and

vibrating presser foot are moving into position for

the next stitch, such as the 111 W 155.

Perhaps the description of the feed mechanism

gave you a hint that the class 111 sewing machine

is a more complicated machine than the class 31.

It is indeed.

Timing the 111 W Class

Sewing Machines

The first step in timing the 111 W machine is

to set the feed driving eccentric on zero stitches

per inch (0 spi). Set the needle bar. With the needle

bar in its lowest position (needle bar crank in the

horizontal position, the rounded portion on the

top and driving stud at the bottom), the

connecting link will be vertical. Set the needle bar

with the upper timing mark just visible at the base

of the needle bar rock frame, and tighten the

needle bar pinch screw. The needle bar is then

properly set.

To set a needle bar that has no mark, set the

feed eccentric for eight stitches to the inch. Then

set the needle bar so that when it rises 3/32 inch

from its lowest position and the point of the

sewing hook is at the center of the needle, the

needle eye will be about 1/16 inch below the hook

point.

The next step is to time the arm shaft with the

hook drive shaft. With the connection belt

removed, rotate the balance wheel toward the

operator until the thread take-up lever is at its

highest point, then aline the arrow on the hook

drive shaft collar with the timing plate arrow, and

replace the connection belt. Rotate the balance

wheel and check. The next step is to center the

feeding action. For this step the feed driving

eccentric must be set on zero spi. With the needle

entering the feed dog, center the needle in the hole

9-21