239.236

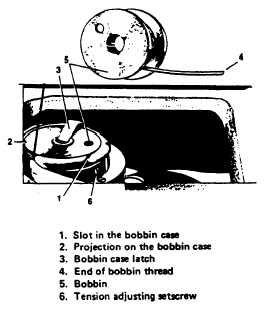

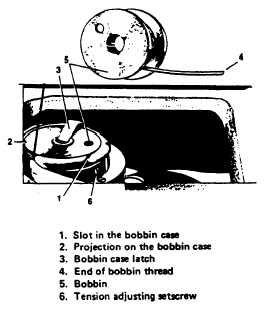

Figure 9-30.-Bobbin case threaded.

Winding the Bobbin

To wind the bobbin and adjust the bobbin

winder, follow the procedure given for the 31-15

sewing machine.

Replacing the Bobbin and Threading

the Bobbin Case

Hold the bobbin between the thumb and

forefinger of your right hand with the thread

drawn out on the bottom from left to right. Place

the bobbin on the center stud of the bobbin case;

then push down the latch.

Draw the thread into the slot (1), and under

the back of the projection (2). Leave a loose end

of thread about 2 inches long above the slide.

When closing the slide plate, leave just enough

space for the thread to pass through when it is

first picked up by the needle.

Regulating the Tension

The tension on the needle thread is regulated

by the tension thumb nut located at the front of

the tension disks on the front of the machine. To

increase the tension, turn this thumb nut

clockwise. To decrease the tension, turn the

thumb nut counterclockwise.

The tension on the bottom (bobbin) thread is

regulated by means of the small screw nearest the

center of the tension spring in the outside of the

bobbin case (l), as shown in figure 9-30. To

increase the tension, turn this screw clockwise. To

decrease the tension, turn the screw

counterclockwise.

Regulating the Length of Stitch

The number of stitches per inch is stamped on

the stitch indicating disk, which can be seen

through the hole on the uprise.

To change the length of stitch, press down the

feed regulating stud (plunger), located in the bed

of the machine. At the same time, turn the balance

wheel slowly until the plunger enters a notch in

the adjustable feed eccentric disk. Continue to

hold the plunger and turn the balance wheel

forward or backward until the number of stitches

per inch desired can be seen through the hole in

the front of the uprise. Disengage the plunger by

releasing it.

Regulating the Pressure

on the Material

The pressure on the material is regulated by

the presser bar regulating screw at the back of the

sewing machine. The screw acts on a flat spring.

To increase the pressure, turn this screw

downward. To decrease the pressure, turn this

screw upward. The pressure should be only heavy

enough to enable the feed to move evenly along

whatever thickness of material you are using.

Preparing for Sewing

With the left hand, hold the end of the needle

(machine) thread, leaving it slack from the hand

to the needle. Turn the balance wheel over toward

you until the needle moves down and up again

to its highest position. If the sewing machine is

properly timed, this will bring the bobbin thread

up with the machine thread through the hole in

the feed dog. Lay the threads back under the

presser foot and close the slide.

Place the material under the presser foot.

Lower the presser foot either by hand or by the

knee lift, and begin to sew. Start the sewing by

turning the balance wheel over toward you as you

depress the treadle.

Removing the Work

After the machine has stopped, move the

thread take-up lever to its highest position. Raise

9-25