239.450

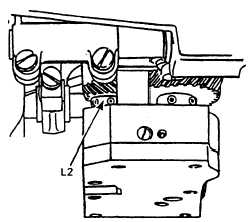

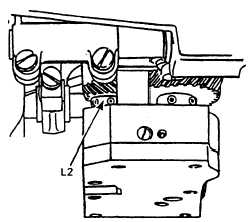

Figure 9-35.—Timing tbe sewing hook.

under the hole in the bobbin case. (See figure

9-35.) Turn the screw into raise the hook, and

out (while pressing down on the hook) to lower

it. The gauge should barely pass between the

throat plate and bobbin case stop finger.

Retighten the Allen setscrews and turn the

adjusting screw in so that a slight tension is left

on the screw.

SETTING SEWING HOOK TO OR FROM

NEEDLE.— To set the relative position of the

hook saddle to the needle, loosen the hook saddle

adjusting screws (fig. 9-36) and slide the hook

saddle to the right or left, as necessary, to set the

point of the hook as close to the needle as possible

(without actually touching). After setting the hook

saddle, check the clearance between the hook

drive gear and the face of the hook saddle. This

clearance should be 0.008 inch; if it is not, reset

it by loosening the screw and setscrew in the hook

drive gear, and move the gear to the right or left

to get the proper clearance.

TIMING BOBBIN CASE OPENER.— To set

the bobbin case opener, turn the balance wheel

toward the operator until the lower timing mark

on the needle bar is barely visible below the needle

bar frame on its upward stroke. Tip the machine

back and loosen the two Allen screws in the

bobbin case opener drive gear; then line up the

timing marks by turning the opener shaft with a

screwdriver. The timing marks are located as

follows: one on the flange of the opener, and the

other on the hook saddle (fig. 9-35). Adjust the

opener so it lightly touches the bobbin case and

turns it enough to make a sufficient opening for

a free passage of thread between the bobbin case

stop finger and the throat plate. Tighten the

screws in the bobbin case opener drive gear.

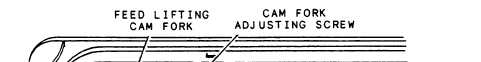

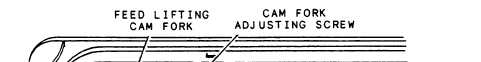

RAISING OR LOWERING THE FEED

DOG.— To raise or lower the feed dog, remove

240.85

Figure 9-36.—Hook saddle assembly showing bobbin case raceway oil reservoir.

9-28