Bobbin and Bobbin Case

The procedure for removing the bobbin case,

winding the bobbin, threading the bobbin case,

and replacing the bobbin case is the same as for

the 31-15 sewing machine. The only exception to

this is that when the bobbin case is threaded, the

thread should be drawn from the BOTTOM from

left to right, instead of from the top as given for

the 31-15.

Threading the Needle

These machines are threaded in the same way

as the 111 series machines, described earlier in the

chapter. When threaded up to the needle, thread

the needle from the front through the eye to the

back. The long thread groove should be in front

when the needle is properly set in the needle bar.

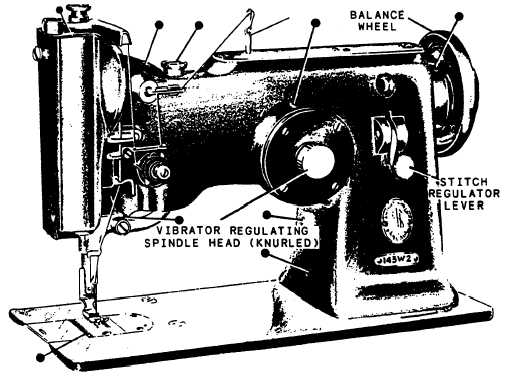

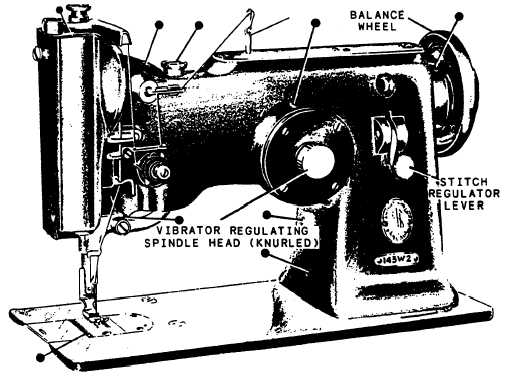

Regulating the Length of Stitch

To adjust the length of stitch, depress the

stitch regulator lever (fig. 9-39) on the uprise and,

at the same time, turn the balance wheel forward

until the lever engages in the notch in the stitch

regulator flange. Hold the lever in the notch and

turn the balance wheel backward or forward (as

necessary) until the desired number of stitches per

inch is shown opposite the arrow on the stitch

regulator.

Regulating the Width of the Zigzag

The extreme width of the zigzag (needle throw)

on the 143 W 2 is 3/16 inch; it is 5/16 inch on

the 143 W 3. The width of bight is regulated by

turning the knurled knob on the needle vibrator

regulating spindle head (fig. 9-39) at the front of

the machine. To increase the width of the stitch,

turn the regulating spindle head to the left, and

to the right to decrease.

Setting the Needle Bar

The two adjustment marks on the needle bar

are 3/32 inch apart. To set, insert the needle bar

up into the needle bar frame so the upper mark is

just visible at the lower end of the needle bar

frame with the bar at its lowest position. The eye

of the needle should be 1/16 inch below the point

239.293

Figure 9-39.—Oiling points at the front of the 143 W 2.

9-31