you with your right hand until the needle moves

down and up again to its highest position.

3. Pull the needle thread gently and the

bobbin thread will come up with it through the

hole in the needle plate.

4. Place both ends of the thread beneath and

in back of the presser foot.

5. With the needle at its highest point, place

the material to be sewn beneath the presser foot

and fully lower the presser foot lifter lever.

6. Start sewing.

Regulating the Tension

Tension is the key word to good sewing. For

perfect stitching, the tension of the upper and

lower threads should be balanced and just

sufficiently tight to lock both threads in the center

of the material (look again at figure 9-16).

The machine is correctly adjusted to make a

perfect stitch before leaving the factory. When

adjustments do become necessary, the problem

is more likely to be caused by the upper thread

tension, so always begin there. To adjust the

upper thread tension, proceed as follows:

1. Lower the presser foot. Remember upper

thread tension adjustments must be made with the

presser foot down.

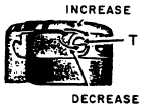

2. Check the upper thread tension. If it is

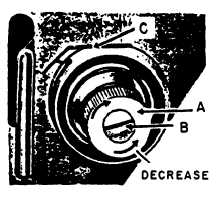

loose, turn the tension nut (A in fig. 9-43)

239.452

Figure 9-43.—Upper thread tension.

clockwise to increase the tension; if the upper

thread tension is tight, turn the tension nut

counterclockwise to loosen it.

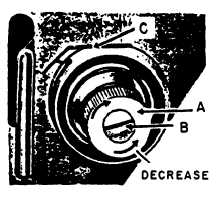

Adjusting the Bobbin Thread Tension

When you find it necessary to adjust the

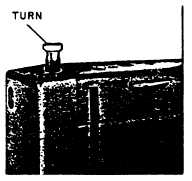

bobbin thread tension, turn the tension screw

(T of fig. 9-44) on the bobbin case clockwise to

increase the tension, and turn the screw

counterclockwise to decrease the tension.

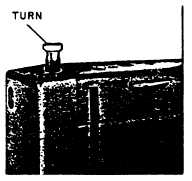

Regulating the Pressure

of the Presser Foot

The pressure of the presser foot should be

adjusted according to the type of material being

sewn. The heavier the material, the heavier the

pressure. The lighter the material, the lighter the

pressure. The pressure should be only heavy

enough to prevent the material from rising with

the needle and to enable the feeder mechanism

to move the work along evenly. The pressure

becomes tighter as the regulating thumbscrew is

turned clockwise, and looser as the thumbscrew

is turned counterclockwise (fig. 9-45).

239.453

Figure 9-44.—Bobbin thread tension.

239.454

Figure 9-45.—Adjusting the presser foot pressure.

9-35