239.455

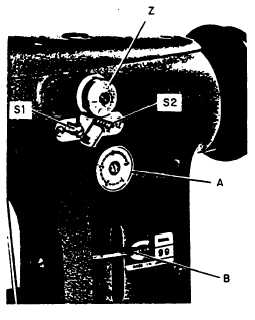

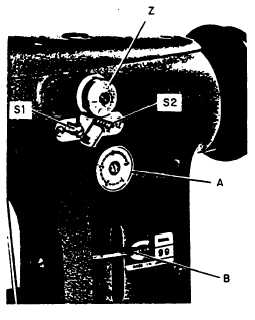

Figure 9—46.-Stitch regulator.

Stitch Regulator and Reverse

Sewing and Tacking

For reverse sewing and tacking, proceed as

follows:

1. When the number 1 on dial A of figure 9-46

is set uppermost on a vertical line, the feeder does

not move the material.

2. When the dial (A) is turned counter-

clockwise and lever (B) is raised as far as it will

go, the machine makes forward stitches, in-

creasing in size as the dial knob is turned toward

the larger numbers.

3. For reverse sewing, lower the lever (B) as

far as it will go.

4. By moving the lever up and down during

sewing, you can easily make forward or reverse

stitches continuously and at will. You can make

use of this feature for locking the thread at the

start or end of seams.

Straight and Zigzag Sewing

Be sure that stops S1 and S2 are set at the

extreme ends of their slot. If not, use a screwdriver

to loosen them about one turn, and then tighten

them in their extreme positions. Turning the

zigzag regulating knob Z clockwise as far as it will

go causes the machine to sew with a straight stitch.

Turning this knob counterclockwise produces a

zigzag stitch. The zigzag becomes wider the more

this knob is turned in a counterclockwise direc-

tion. The widest zigzag stitch is sewn when knob Z

cannot be turned any further. This occurs when

the pointer at the underside of knob Z points at

the largest number on the dial and is stopped by

stop S2.

When you want to control the width of the

zigzag between certain minimum and maximum

limits between the numbers on the dial, use a

screwdriver to set stops S1 and S2 to the selected

widths. Be sure to set stop S1 as far to the left

as possible when a straight stitch is desired.

NOTE: The zigzag regulating knob can be

moved into any desired position while the

machine is operating. Do not turn the

zigzag regulating knob when the machine

is at rest and the needle is in the material.

If you do you may bend or break the

needle. Turn the handwheel toward you to

raise the needle out of the material before

operating the regulating knob.

Preparing the Machine for Rope

Stitching (Model 99R-3 only)

For rope stitching, the standard combination

of presser foot, feed dog, and (throat) needle plate

is replaced with a special set of components

designed specifically for this purpose. To do this,

move slide plate (S of fig. 9-47) as far to the left

239.456

Figure 9-47.—Rope stitching.

9-36