239.367A

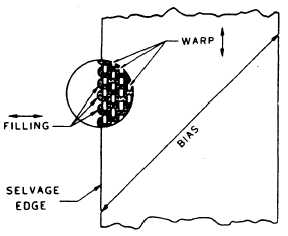

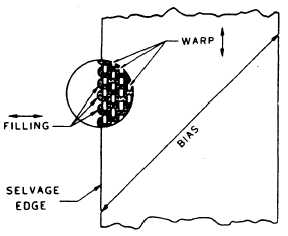

Figure 10-1.—Textile terms.

Selvage and Raw Edges

The selvage edges of material, as shown in

figure 10-1, are the edges of cloth, tape, or

webbing that are woven to prevent raveling. When

the material is cut, the resulting edge at the cut

is referred to as a raw edge.

Warp

There are threads that run lengthwise of the

cloth parallel to the selvage edge. If there is a

difference in the strength of the warp and filling

threads, the warp threads are usually stronger,

because they form the framework for the material

and support most of the strain during the weaving

process. Figure 10-1 shows both warp and filling

threads.

Filling

Filling is also referred to as a woof, weft, or

pick. It is the threads that run crosswise to the

cloth as it comes from the loom. This term is not

to be confused with filling in the sense of sizing,

which means the addition of substances that give

body or decrease porosity of the material. Warp

and filling threads must be determined in pattern

layout because patterns (unless otherwise stated)

are always cut with the warp and filling.

Weave

The weave is an interlacing of two sets of

threads (warp and filling) to form a specific

pattern. The manner in which the material is

woven or constructed affects many of the cloth

properties,

such as tensile strength, air

permeability, and elongation.

Bias

A bias is a diagonal line of a cut, a fold, or

a seam across a piece of textile material at an angle

of 45 degrees to the direction of the filling threads

in the material. Bias construction is used to save

material, prevent tearing between sections, and

provide elasticity where it is a requirement for a

satisfactory performance of the article. The bias

direction of the fabric has a greater stretching

quality than the straight direction. A bias cut is

shown in figure 10-1.

Tensile Strength

The force required to break a material is called

tensile strength. The tensile strength of a fabric

is stated in pound-per-inch width for warp and

filling. The tensile strength of webbings and tapes

is stated for the full width.

Cloth Weight

The cloth weight is the weight of a cloth, or

fabric, in ounces per square yard. All fabrics have

a designated cloth weight. For instance, a square

yard of cotton duck may weigh 8 ounces;

therefore, it is called 8-ounce duck.

CONSTRUCTION FEATURES

AND USES OF VARIOUS TEXTILE

MATERIALS

If a cigar ash burns a hole in your tweed

jacket, you will not patch it with a piece of velvet

material. If a life raft needs repair, you will not

use tweed fabric to repair it. Or, if an NES 12

canopy needs repair, you won’t use 7.25-ounce

nylon duck. If a repair is to make an item usable,

must use like material.

In the not too distant past we were limited to

natural fibers as a source for our fabrics and

associated materials; but today, with the advent

of synthetic fibers,

we can enjoy their

improvements in some respects over the natural

fiber. Currently the natural and synthetic fibers

have their respective advantages and

disadvantages. Because you cannot use synthetic

or natural fiber materials exclusively, you must

decide which one best serves your purpose. There

10-2