239.367B

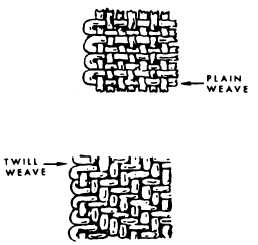

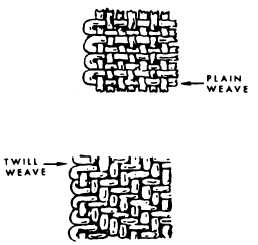

Figure 10-2.—Basic weaves.

are many, many different types of fabrics, or

cloth. When we say cloth, we mean any textile

material over 12 inches wide from selvage to

selvage.

The construction of cloth is determined by

many factors, such as tightness of yarn twist,

number of threads per inch, porosity of the yarns,

and the type of weave used in its formation. The

weave is one of the most important factors. The

two basic weaves are plain and twill (as shown

in figure 10-2). The plain weave is the simplest

method of weaving and gives the smoothest

surface of the fabric. It consists of the filling

threads passing over one warp thread and under

the next warp thread. The twill weave is a more

complicated weave in which the filling threads

pass over and under more than one warp thread,

thereby producing a surface on the fabric that is

generally recognized as a diagonal pattern.

Cotton

Cotton is a natural plant fiber, usually white.

The fibers or “staples” are between 3/8 and 2

inches in length. Chemically, it is almost pure

cellulose. Cotton fabrics, webbing, and tapes

absorb water readily unless treated. They dry

more slowly than the synthetic fabrics and are

more susceptible to mildew and fungus growth.

One should never ignore the presence of mildew

because it seriously affects the tensile strength of

cotton and other fabrics. Heat is less damaging

to cotton than to the synthetics. Insect damage

should, however, always be considered because

cotton is a food for certain cellulose-eating insects,

and cotton makes good nesting or cocoon-

spinning material for rodents and insects.

Nylon

This is a synthetic fiber of extreme toughness

and elasticity. It absorbs very little water, dries

quickly, is mildewproof, and is not affected by

most ordinary oils, greases, or cleaning fluids. It

is also mothproof. It is sensitive to some chemical

fumes, excessive heat, and direct rays of sunlight.

Nylon melts and drips when it is subjected to fire.

This characteristic requires that precautions be

taken when nylon is worn where there is a risk

of fire. Melted nylon on the skin can cause the

most serious of burns.

NOMEX Fabric

NOMEX is the trade name for a fabric that

is used in the construction of flight suits. NOMEX

fabric is a high-temperature resistant and

inherently flame-retardant synthetic fabric. This

fabric has no melt point or drip characteristics

when it is subjected to fire. NOMEX material is

light in weight, does not support combustion, but

begins to char at 700° to 800 °F. The fabric,

similar to nylon, is abrasion resistant, and is also

nonabsorbent.

Duck

This is a comparatively firm, coarse, plain-

weave, cotton fabric with weight per square yard

from 6 to 50 ounces. Duck is frequently called

canvas. It is primarily used in the construction of

protective covers because of its durability and

wearing characteristics.

Rubber and rubberized fabrics are used

in the manufacture of exposure suits and

flotation equipment because they are water-

tight. Rubberized materials are susceptible

to deterioration if subjected to heat and

mildew. Foam rubber is thick and resilient and

is used for padding in upholstery and aircraft

crash pads.

10-3