of the hook, and the long thread groove toward

the operator.

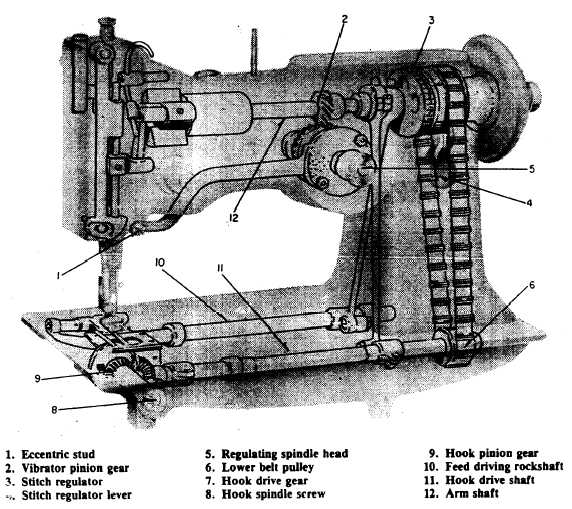

Setting and Timing the Needle Bar Frame

Turn the regulating spindle head all the way

to the right. This will cause the machine to sew

a straight stitch. The needle should be centered

in the hole in the throat plate. If not, loosen the

setscrew that holds the eccentric stud (1) and turn

the stud until it is centered (fig. 9-40.) Turn the

needle regulating spindle head (5) to the extreme

left for the widest throw. Turn the balance wheel

forward until the needle is at its lowest position.

The needle bar should start to move in a sideward

movement as the needle starts to rise. If it does

not, you must advance or retard the vibrator

pinion gear (2), shown in figure 9-40.

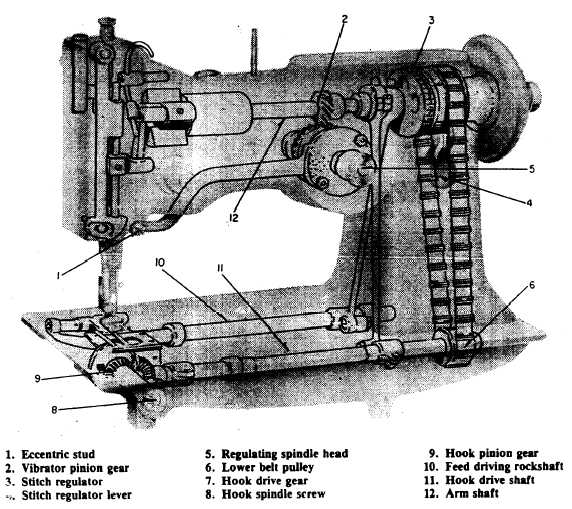

Timing Sewing Hook

Turn the balance wheel toward the operator’s

side until the needle bar is all the way down and

has risen until the lower timing mark is just visible

below the needle bar frame. Loosen the setscrews

(10) in the lower belt pulley (fig. 9-41) and set the

hook point to the center of the needle eye.

Retighten the setscrews.

Setting the Hook Distance

To or From Needle

Loosen the two hook shaft retaining screws

(8) (fig. 9-41) and the two screws in the hook

pinion gear (7), and slide the hook to the correct

position. Retighten the hook shaft retaining

screws. Set the gear in the proper place on the

shaft—gear aligned with hook drive gear-and

240.92

Figure 9-40.-X-ray view of zigzag sewing machine.

9-32