guide (10), which is located on the needle clamp.

The needle is now threaded from left to right

through the eye of the needle (11). After the needle

is threaded as shown in figure 9-19, pass the

thread down through the hole in the lifting presser

foot (12). Draw about 4 inches of thread through

the hole in the lifting presser foot with which to

begin sewing.

Notice that the lubricating cup has been

bypassed. No lubricant is used on the threads and

cords used in the manufacture or repair of

parachutes.

Removing the Bobbin

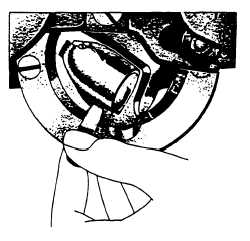

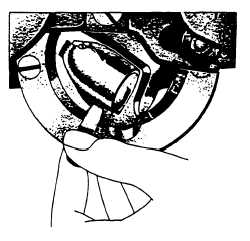

Turn the balance wheel forward to bring the

needle bar and thread take-up lever to its lowest

position. With the aid of the shuttle opening tool

or a small screwdriver, insert the blade end in the

slot in the spring latch beneath the shuttle cylinder

(fig. 9-20). Press the latch away from the cylinder

and it will swing out. The bobbin will then slide

out of the shuttle cylinder.

Winding the Bobbin

Place the bobbin on the bobbin winder spindle

and push it up closely against the shoulder. The

small pin in the shoulder must enter the slot in

the bobbin.

Pass the thread from the thread stand through

the hole in the left side of the bobbin from the

inside. Push the bobbin winder pulley up against

the balance wheel, and place the bobbin winder

Figure 9-20.—Removing the bobbin

cylinder.

239.277

from the shuttle

239.278

Figure 9-21.—Replacing the bobbin.

latch in position. Raise the presser foot and start

the machine. The end of the thread should be held

until a few turns are wound on the bobbin to

prevent slipping. When sufficient thread has been

wound on the bobbin, the bobbin winder will stop

automatically.

Replacing the Bobbin and

Threading the Shuttle

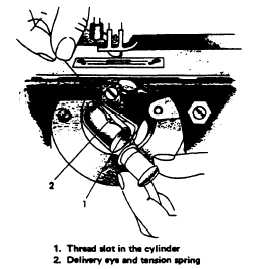

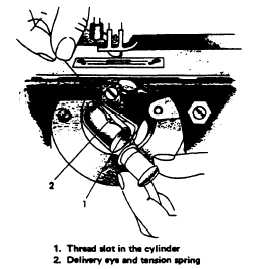

Take the bobbin between the thumb and

forefinger of the left hand, as shown in figure

9-21. The free end of the thread should be drawn

off from the underside toward the right. Place the

bobbin in the shuttle cylinder as far as it will go.

Draw the thread into the slot in the cylinder and

under the tension spring into the delivery eye.

Push the shuttle cylinder in until it is locked by

the spring latch. There should be about 3 inches

of thread hanging free from the shuttle with which

to begin sewing.

Regulating the Tension

The tension on the needle thread is regulated

by the thumb nut at the front of the thread

retainer disks. The tension on the thread retainer

disks should be just enough to cause the tension

wheel to turn when the thread is taken from the

spool.

The tension on the bobbin thread is regulated

by the small screw that holds the tension spring

to the shuttle cylinder. To increase the tension,

9-16