239.273

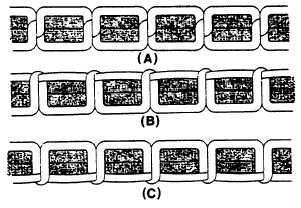

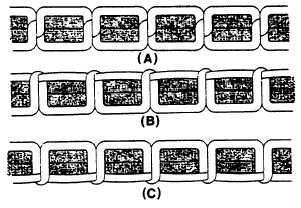

Figure 9-16.—Properly and improperly adjusted tensions.

For ordinary stitching, the needle and bobbin

threads should be locked in the center of the

thickness of the material, as shown in figure 9-16,

view A. When adjusting the tensions, you will not

have a cross section of the stitch.

If the tension on the needle thread is too tight,

or if the bobbin tension is too loose, the thread

will lie straight along the upper surface of the

material and appear as small loops, as shown in

figure 9-16, view B.

If the tension on the bobbin thread is too tight,

or if tension on the needle thread is too loose, the

bobbin thread will lie straight along the underside

of the material, as shown in figure 9-16, view C.

Regulating the Length of a Stitch

The length of a stitch can be checked at the

time the tension of the stitch is checked, as a trial

run of stitches is necessary during both

procedures.

The length of a stitch is regulated by the

thumbscrew in the slot on the front of the uprise

of the machine. To LENGTHEN the stitch,

loosen the thumbscrew and move the lever

DOWN. To SHORTEN the stitch, loosen the

thumbscrew and move the lever UP. When the

desired length of stitch has been obtained by test

running the machine on scrap material, tighten

the thumbscrew.

Regulating the Pressure on the Material

Pressure on the

pressure-regulating

material is regulated by the

thumbscrew on top of the

machine face. To increase the pressure, turn the

thumbscrew clockwise. The pressure should be

just heavy enough to enable the feed dog to move

the work along evenly.

Removing Work

Hand-turn the balance wheel toward you until

the thread take-up lever is at its highest position.

Raise the presser foot, either by the hand lever

or by the knee lift, and draw the work and threads

straight behind the presser foot. Cut the threads

close to the material, leaving free about 2 inches

of bobbin and machine thread.

Adjusting the Thread Take-up Spring

The thread take-up spring (fig. 9-15) should

be set so that when the eye of the needle reaches

the material on the downward stroke of the needle

bar, the spring will be through acting on the

thread, and will rest against the stop of the thread

take-up spring regulator.

If the thread take-up spring is not correctly

set, loosen the setscrew (2) in the arm of the

machine and turn the tension adjusting stud to

the right for more movement of the spring, or to

the left for less movement. When the spring is

correctly set, retighten the setscrew.

The tension on the thread take-up spring

should be just sufficient to take up the slack of

the needle thread until the eye of the needle

reaches the material on its descent. To increase

the tension on the thread take-up spring, loosen

the tension adjusting stud and move the take-up

spring from the recess in the regulator to the right

between the regulator and the tension disks. When

the required tension is obtained, securely tighten

the tension adjusting stud and move the spring

back into its position in the regulator recess. To

decrease the tension, move the spring to the left

between the regulator and the tension disks.

SINGER SEWING MACHINE 7-33

The class 7-33 sewing machine is a lockstitch

heavy duty machine, and is intended for use in

sewing heavy canvas, webbings, and other

material not adaptable to the lighter duty sewing

machines. The only difference between the 7-31

and the 7-33 is that the 7-33 has the clutch on the

motor, while the 7-31 has the clutch on the balance

wheel. The operation and maintenance techniques

are identical. The procedure for operating the 7-33

sewing machine is the same as for the 31-15 sewing

machine.

9-13