Adjusting the Feed Dog

The height at which the feed dog should be

set depends on the weight and number of plies

of the material being sewn. If the feed dog is set

too low, the material does not feed through the

machine; if it is set too high, it may cut or fray

the material. The recommended height of the feed

dog for sewing lightweight canopy material is

slightly less than one tooth above the throat plate.

If you are sewing heavier material, raise the feed

dog to a height that ensures positive feeding of

the material. After you have decided on the

correct height for the project you are working on,

adjust the feed dog accordingly, by loosening and

then tightening the screw, as shown in figure 9-7.

You must remember that each time the height of

the feed dog is changed, the feeding mechanism

may be out of time. For this reason, set the feed

dog first, and then make the necessary adjustment

on the feeding mechanism. Since most of your

canopy repairs involve material of approximately

the same weight, one-time adjustment of the feed

dog is usually sufficient. Repeated changing of

its height is not necessary.

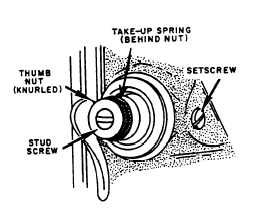

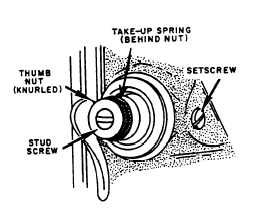

Adjusting the Thread Take-up Spring

To adjust correctly the take-up spring in the

tension assembly (fig. 9-8), you should first

understand its normal operation. The thread take-

up lever pulls the thread take-up spring down

about even with the slack thread regulator while

the needle is going up. While the take-up lever

is coming down with the needle, the thread take-

up spring pulls the slack out of the thread and

keeps it from getting under the needle. If you do

not have this adjusted properly, a loop can form

239.445

Figure 9-8.—Tension assembly.

over the needle hole in the throat plate, and the

needle can split the thread as it enters the needle

hole. You should set the spring about 1/4 inch

above the slack thread regulator. The thread take-

up spring should be set so that the spring will have

completed its downward motion and be resting

on the stop when the needle, on its downstroke,

reaches the fabric.

To adjust the spring, loosen the setscrew, as

shown in figure 9-8. To put more tension on the

spring, you turn the assembly clockwise; to put

less tension on the spring, you turn the assembly

counterclockwise.

It may be necessary for you to replace the

thread take-up spring because it can bend and

become weak. Loosen the setscrew and insert a

screwdriver into the slot of the tension screw stud

(fig. 9-8). Turn the stud to the left until it is

screwed out of the thread take-up spring

regulator.

Remove thumb nut (fig. 9-8), the tension

spring, and tension discs. The take-up spring is

now free for removal. After replacing the old

spring with a new one, assemble the parts in

reverse procedure.

Replacing the Needle

While replacing a needle is a relatively simple

job, you must know a few things about needles

in order to decide which needle is required when

a needle must be replaced. It is very important

that the proper needle be used to ensure good

machine operation. The selection of needles by

class, variety, and size for different machines and

materials is necessary to eliminate thread

breakage, needle breakage, skipped stitches, and

fraying of the thread.

Needles for the various machine classes are

selected and ordered by needle number and size.

The needle numbers consist of a class number and

variety number separated by a‘‘x”; for-example,

the class and variety needle 16 x 87 is used in the

31-15 sewing machine. Cloth point needles are

round, sharp-pointed needles used for sewing

cloth, since they do not cut the strands as they

are forced between the woven threads of the

fabric. Many different varieties of cutting point

needles are available, but they are used only for

sewing heavy leather. Figure 9-9 shows the shape

of the openings made in material by the cloth

point (view A), twist point (view B), and the

diamond point (view C). Figure 9-9 illustrates why

it is important that a round-pointed needle be used

in cloth; views B and C show how cutting point

needles can cut the warp and filler threads.

9-8