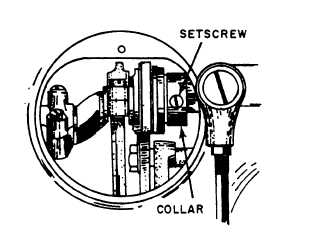

2. Move the needle bar up or down as

required; and then tighten the screw.

239.443

Figure 9-6.—Timing needle with shuttle.

be in proper time for the machine to function

properly. See figure 9-6.

Timing the Needle with the Shuttle

If a class 31 sewing machine does not form

the lockstitch, if it skips stitches, or if it frays or

breaks thread, the needle is not moving in the

proper relationship with the shuttles motion. First

make sure you have the right needle. Check the

needle for the correct class, variety 16 x 87, and

size. Insert the needle in the needle bar (long

groove to the left) as far as it will go (fig. 9-6).

Next compare the needle stroke to the shuttle

stroke. To do this, remove the throat plate. Turn

the balance wheel toward you until the point of

the shuttle on its forward stroke reaches the center

of the needle while the needle is on the upstroke.

At this time, the needle bar should have risen 1/10

inch and the point of the shuttle should be 1/16

inch above the eye of the needle, as shown in A

o f figure 9-6.

NOTE: Prior to making adjustments to the

sewing machine, always follow the

troubleshooting chart in Table 9-1.

If the needle eye is not in this position, the

following steps should be taken:

1. Loosen the needle bar connecting stud

screw, as shown in B of figure 9-6.

3. Rotate the balance wheel through the full

cycle to check the timing.

4. Replace the throat plate.

Timing the Feed Dog with the Needle

The feed driving eccentric is an adjustable

connection between the arm shaft (the shaft in the

head) and the feed rock shaft (first shaft beneath

the bed of the machine). If the feed mechanism

is properly timed, the feed dog should be on its

downstroke and level with the throat plate when

the point of the needle reaches the material. If

there is a twisted knot every 1 to 2 inches on the

bottom of your material, check the timing of the

needle before adjusting the feed mechanism.

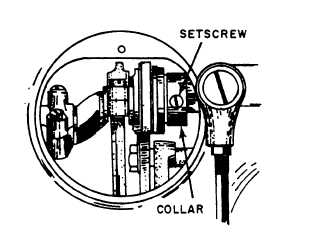

To adjust the feed eccentric, first lower the

stitch regulator to the lowest position so the

machine forms its longest stitch. Turn the balance

wheel until the feed dog is on its downstroke and

is flush with the throat plate. Move to the rear

of the machine and take off the arm side cover.

Turn the balance wheel away from you until the

feed eccentric collar setscrew is visible (fig. 9-7).

Hold the collar with your left thumb. Loosen the

screw and rotate the balance wheel away from you

until the needle, on its downstroke, reaches the

material. Tighten the setscrew. Rotate the balance

wheel to check the timing. Recheck the timing of

the shuttle point with the needle. When you time

the feeding mechanism, you may throw the needle

out of time with the shuttle.

239.444

Figure 9-7.—Feed eccentric.

9-6