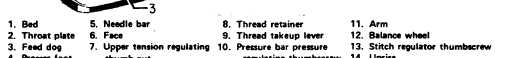

239.262

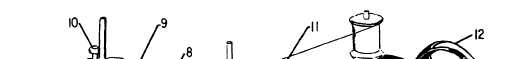

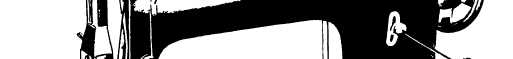

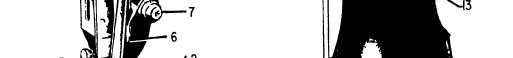

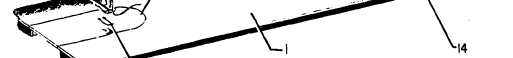

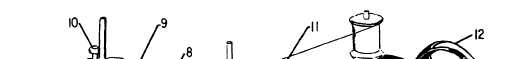

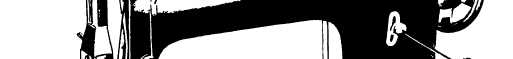

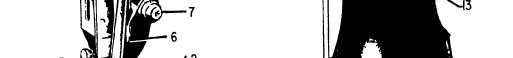

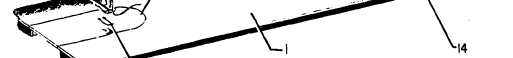

Figure 9-2.—Sewing machine 31-15.

The machine is powered by an electric motor,

which is connected to the motor driving pulley by

a clutch. You connect the motor to the clutch by

pressing the forward part of the foot treadle. The

aft part of the treadle is the brake, which acts

upon the clutch.

The material to be sewn is held in position on

the feed dog by the presser foot. The pressure of

the presser foot upon the material enables the feed

dog to push the material forward each time the

needle goes up. The pressure of the presser foot

on the material is released either by a knee lifter

or a hand lifter. The presser foot can be raised

by pushing the knee lifter to the right. The hand

lifter is located behind the face of the machine.

The presser foot may be lifted and locked into

position by raising the hand lifter to its highest

position.

OSCILLATING TYPE SEWING

MACHINES

Two of the most commonly used oscillating

sewing machines are the 31-15 and 7-33, both of

which are discussed in this chapter.

SINGER SEWING MACHINE 31-15

When starting out as a PR, the 31-15 sewing

machine will probably be the one you’ll like to

use. This machine is smaller and lighter than most

of the other machines used in the parachute loft.

The manufacturer calls the 31-15 a tailoring

machine. It is used to sew and repair clothing,

uniforms, shirts, flying clothing, jackets, and

lightweight protective covers.

The 31-15 is an oscillating sewing machine that

has a recommended speed of 2,200 stitches per

minute and makes a lockstitch. It is very good for

sewing nylon cloth, and can be used for sewing

lightweight canvas up to 8 ounces. The number

of stitches can be regulated from 7 to 32 stitches

per inch.

When the 31-15 machine is in operation, the

balance wheel turns over toward the operator.

When hand-turning the balance wheel, always

rotate it in this direction. The components of the

Singer Sewing Machine 31-15 are shown in figure

9-2.

9-3