indicate that the cylinder being recharged isn’t

receiving anymore CO2. If you haven’t reached

the gross weight required (tare weight plus weight

of charge) start the compressor and complete

charging. Stop the compressor upon reaching the

proper gross weight. At this time, you have

completed the recharging process, and you must

secure the equipment.

10. To shut the equipment down, start by

securing the inflation assembly valve, and shut off

the compressor. Then secure the fill line valve.

Open the relief valve; this will relieve any pressure

you may have in the line between the fill line valve

and the inflation assembly. Disconnect the fill line

from the inflation assembly and remove the

charging adapter. To secure the rest of the system,

all you have to do is close the supply cylinder valve

and bleed the system by opening the fill line valve.

If, during the recharging process, the cylinder

being charged ceases to gain in weight, there may

be one of two things wrong:

1. The supply cylinder may contain less than

10 pounds of carbon dioxide. In this case, a fully

charged supply cylinder should be used and the

partially charged cylinder reserved to start the

recharging of an empty cylinder.

2. The connecting lines may have become

stopped up with carbon dioxide snow. This may

be caused by water in the supply cylinder or too

small a valve passage (less than 1/8 in) in the

supply cylinders. In this case, the disc assembly

(disc-type valve) or the cylinder valve (seat-type

valve) should be securely seated and the pump

shut off. The connections should be broken and

cleared of the carbon dioxide snow. The line will

actually clear itself if allowed to stand for some

length of time, but this can be hastened by

applying a flame or torch to the tubing. The line

should then be blown out with air to clear it of

water or foreign matter.

MAINTENANCE FOR THE C-O-TWO

TRANSFER UNIT

Once every month, inspect the level of the oil

in the crankcase and see that it is within the limits

specified.

Once every 6 months, lubricate the idler shaft

with two or three applications of light cup grease;

also, lubricate the gear teeth with a thin coating

of the same grease. With a small brush, apply a

light coating of Vaseline to the piston rod. To

do this, dip the brush in Vaseline and hold the

brush against the piston rod while rotating the

gears manually until the piston rod has been

coated completely. If necessary, tighten the

packing at the piston stem. A special wrench is

needed for this operation. Do not tighten

excessively. Because of the design of the packing,

it is necessary to make only a snug adjustment

to have it hold tightly.

Keep the commutator or the motor clean.

Under normal operating conditions, the

commutator will require only occasional cleaning

with a dry piece of nonlinting cloth. Never

lubricate the commutator.

Drain and refill the crankcase at least once a

year. The bearing housings of the motor, which

also need attention at this time, should be cleaned

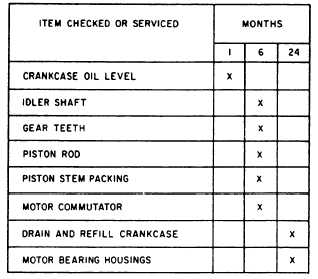

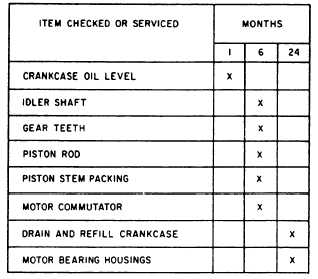

and regressed by a qualified electrician. Use table

8-3 for servicing intervals.

MAINTENANCE OF THE WALTER

KIDDE TRANSFER UNIT

The instruction book on lubrication for the

Walter Kidde transfer unit recommends inspecting

the oil level in the crankcase periodically and

changing it as necessary. Here, experience with

pumps dictates the time of action. One can

establish and maintain a schedule compatible with

the experience gained through operating the

equipment. The plunger packing needs no oil.

Table 8-3.—C-O-TWO Unit Servicing Intervals

8-5