The following practices and procedures help

to ensure safe and smooth operation of the sewing

machine:

1. The balance wheel must always turn toward

the operator.

2. Do not run the machine with the presser

foot resting on the feed dog without material

being under the presser foot.

3. Do not run the machine when both bobbin

case and needle are threaded unless there is

material under the presser foot.

4. Do not try to help the machine by pulling

the material. You may bend or break the needle.

If properly adjusted, the machine feeds the work

without assistance.

5. The slide over the bobbin case should

be kept closed when the machine is in op-

eration.

6. Keep your head away from the thread take-

up lever and needle bar at the top of the sewing

machine face.

7. When running the machine, do not take

your eyes away from the needle and presser foot.

8. Keep your fingers from under the needle.

9. When running the machine, keep your

fingers away from the belt and pulley areas.

10. Never attempt threading the needle when

the machine is turned on.

Lubrication

To ensure easy operation and to prevent

unnecessary wear of the moving parts, all sewing

machines need oiling. When a machine is in

constant use, it should be oiled twice a day. Anew

machine should be oiled more frequently when

in constant use. Use only one drop of oil at each

oiling point. A 10W mineral oil is recommended.

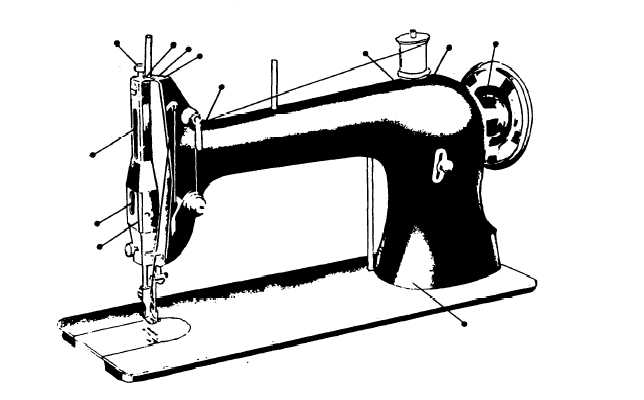

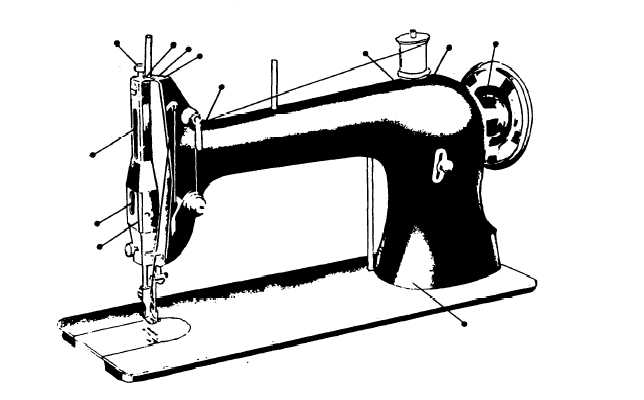

Oiling points for the 31-15 machine are shown

in figures 9-3, 9-4, and 9-5. Oil should be applied

regularly to the shuttle bearing in the shuttle race.

Occasionally, remove the faceplate and apply oil

to the bearings and points that are uncovered.

Timing the 31-15

There are two distinct timing operations for

the 31-15 machine. One operation times the needle

with the shuttle; the other timing operation times

the feed dog with the needle. Both the needle with

the shuttle and the feed dog with the needle must

239.263

Figure 9-3.—Oiling points at the front of the machine.

9-4