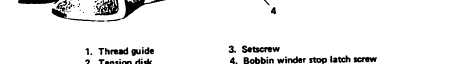

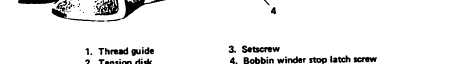

Figure 9-13.—Winding the bobbin.

belt. The bobbin winder is so positioned to allow

the pulley to drop away from the belt when

sufficient thread has been wound on the bobbin.

Figure 9-13 illustrates the bobbin-winding

operation. The procedure is as follows: Place the

bobbin on the bobbin winder and push it on the

shaft as far as it will go. Pass the thread from the

spool down through the thread guide. Loop the

thread around back and through the tension disks.

The thread is then wound around the bobbin

a few times and the pulley pushed up against the

machine belt. The bobbin can be wound while the

machine is being used for sewing. If there is no

material under the presser foot, make certain that

the presser foot is raised and not riding on the

feed dog while winding the bobbin.

When sufficient thread has been wound on the

bobbin, the pulley on the bobbin winder drops

back from the machine belt automatically. If the

thread does not wind evenly on the bobbin, loosen

the setscrew in the tension bracket and move the

bracket to the right or left as required; then tighten

the bobbin winder stop latch screw. The amount

of thread wound on the bobbin is regulated by

the bobbin winder stop latch. To wind more

thread on the bobbin, turn the screw to the right;

to wind less thread on the bobbin, turn this screw

to the left.

239.270

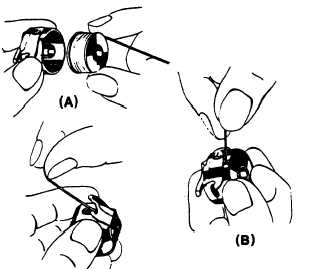

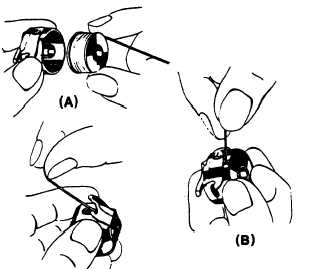

Threading the Bobbin Case

Hold the fully wound bobbin between the

thumb and forefinger of the right hand with the

thread end running over the top toward the right,

as shown in figure 9-14, view A. With the left

239.271

Figure 9-14.—Threading the bobbin case.

9-11