hand, hold the bobbin case as shown, with the

thread slot near the top.

Place the bobbin into the bobbin case and pull

the thread into the slot in the edge of the bobbin

case (view B). Draw the thread down under the

tension spring and into the delivery eye at the end

of the tension spring (view C). When the free end

of the thread is pulled, the bobbin will rotate

clockwise if the bobbin case has been threaded

properly.

Replacing the Bobbin Case

Hold the latch open on the threaded bobbin

case with the thumb and forefinger of the left

hand, with the latch in a horizontal position. Place

the bobbin case on the center stud of the shuttle

body. Release the latch and press the bobbin case

back until the latch catches the groove near the

end of the stud.

Preparing for Sewing

With the left hand, hold the end of the needle

thread, leaving it slack from the hand to the

needle. Turn the balance wheel toward you until

the needle moves down and catches the bobbin

thread. Continue to turn the balance wheel

forward until the needle comes up and brings the

bobbin thread up with the needle thread.

With the thread take-up lever at its highest

position, lay both threads back under the presser

foot .

Commencing

Place the

presser foot,

to Sew

edge of the material beneath the

lower the presser foot, turn the

balance wheel by hand until the needle is in the

material, and press lightly on the treadle. To

prevent fouling the needle thread in the bobbin

case, hold the ends of both threads until the first

few stitches are made.

While sewing, hold the work flat, but do not

pull or push on the material. Let the feed dog

carry the work evenly under the presser foot and

needle. If the operator pulls on the material, the

needle bends, strikes the throat plate, and is either

dulled, or more likely, broken. When the needle

is about to cross a seam or other unusually thick

or uneven place in the work, disengage the clutch,

and hand-turn the machine over the rough place;

otherwise, the needle may be broken or thrown

out of time.

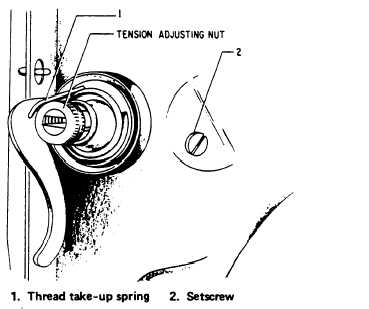

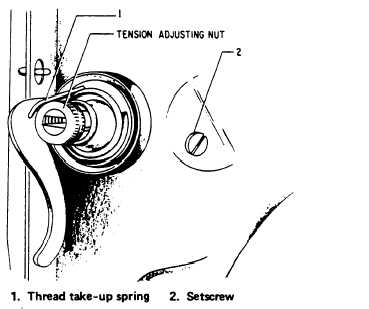

239.272

Figure 9-15.—Adjusting the machine thread tension.

Regulating the Tension

The tension on the needle thread should be

regulated only when the presser foot is down. If

the tension of the machine thread is not correct,

it should be adjusted by turning the tension

adjusting nut, as shown in figure 9-15. To

INCREASE THE TENSION, turn the nut

clockwise; to DECREASE THE TENSION, turn

the nut counterclockwise.

The tension on the bobbin thread is regulated

by the small screw in the bobbin case tension

spring. To increase the tension, turn the screw

clockwise; to decrease the tension, turn the screw

counterclockwise.

This screw is very small and is easily lost

if extreme care is not exercised in backing

it out when the tension is decreased. If the

screw is tightened excessively or is slightly

too long, it will penetrate into the inside

of the bobbin case and prevent removal of the

bobbin.

When the tension on the bobbin thread has

been properly adjusted for a particular size of

thread, it is seldom necessary to change it. A

correct stitch can usually be obtained by varying

the tension on the needle thread, which is an easier

adjustment.

9-12