POWER TOOLS

LEARNING OBJECTIVES: Identify the

different types of power tools. Describe the

uses of different types of power tools. List the

safety precautions that apply to power tools.

List the safety precautions that apply to

extension cords.

Power tools have become so commonplace in the

Navy that all ratings now use them in the performance

of maintenance at one time or another.

The following paragraphs are devoted to the

identification, general-operating practices, and care of

these tools.

DRILLS

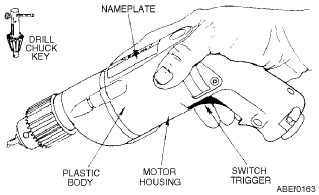

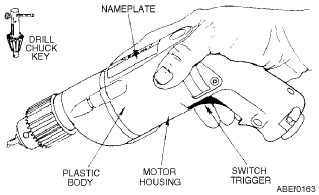

The portable electric drill (fig. 1-59) is probably the

most frequently used power tool in the Navy. Although

it is especially designed for drilling holes, by adding

various accessories you can adapt it for different jobs.

Sanding, sawing, buffing, polishing, screw driving,

wire brushing, and paint mixing are examples of

possible uses.

Portable electric drills commonly used in the Navy

have capacities for drilling holes in steel from 1/16 inch

up to 1 inch in diameter. The sizes of portable electric

drills are classified by the maximum size straight shank

drill it will hold. That is, a 1/4-inch electric drill will

hold a straight shank drill bit up to and including

1/4 inch in diameter.

The revolutions per minute (rpm) and power the

drill will deliver are most important when choosing a

drill for a job. You will find that the speed of the drill

motor decreases with an increase in size, primarily

because the larger units are designed to turn larger

cutting tools or to drill in heavy materials, and both of

these factors require slower speed.

If you are going to do heavy work, such as drilling

in masonry or steel, then you would probably need to

use a drill with a 3/8- or 1/2-inch capacity. If most of

your drilling will be forming holes in wood or small

holes in sheet metal, then a 1/4-inch drill will probably

be adequate.

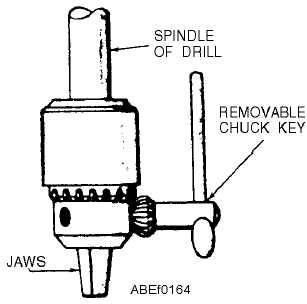

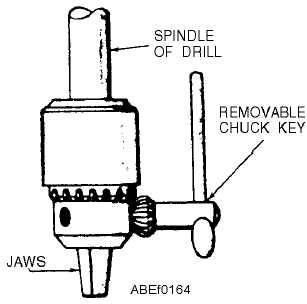

The chuck is the clamping device into which the

drill bit is inserted. Nearly all electric drills are

equipped with a three-jaw chuck. Some drills have a

hand-type chuck that you tighten or loosen by hand, but

most of the drills used in the Navy have gear-type,

three-jaw chucks, which are tightened and loosened by

a chuck key, shown in figure 1-60. Do not apply further

pressure with pliers or wrenches after you hand tighten

the chuck with the chuck key.

Always remove the key IMMEDIATELY after you

use it. Otherwise the key will fly loose when the drill

motor is started and may cause serious injury to you or

one of your shipmates. The chuck key is generally

taped on the cord of the drill; but if it is not, make sure

you put it in a safe place where it will not get lost.

All portable electric drills used in the Navy have

controls similar to the ones shown on the 1/4-inch drill

in figure 1-59. This drill has a momentary contact

trigger switch located in the handle. The switch is

squeezed to start the electric drill and released to stop it.

The trigger latch is a button in the bottom of the

drill handle. It is pushed in while the switch trigger is

held down to lock the trigger switch in the ON position.

The trigger latch is released by squeezing and then

releasing the switch trigger.

1-37

Figure 1-59.—1/4-inch portable electric drill.

Figure 1-60.—Three-jaw chuck and chuck key.