guide, which screws into the underside of the cap. The

die is adjusted by setscrews at both ends of the interval

slot. This type of adjustable die is issued in various

sizes to cover the cutting ranges of American Standard

Coarse and Fine and special-form threads. Diestocks to

hold the dies come in three different sizes.

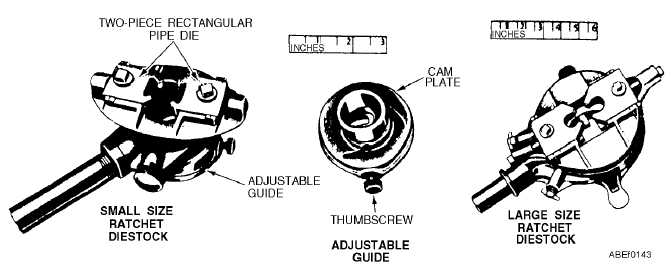

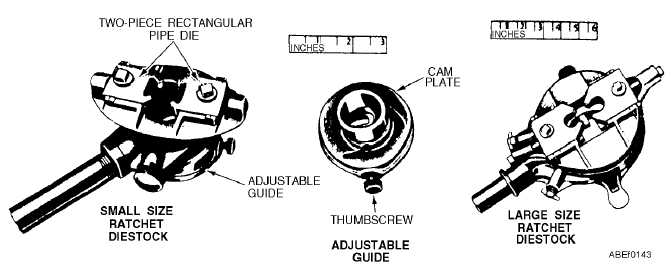

Two-piece rectangular pipe dies (fig. 1-55) are

available to cut American Standard Pipe threads. They

are held in ordinary or ratchet-type diestocks (fig.

1-57).

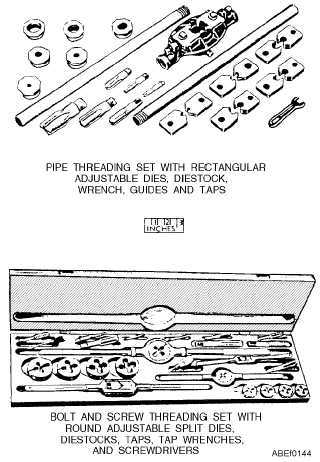

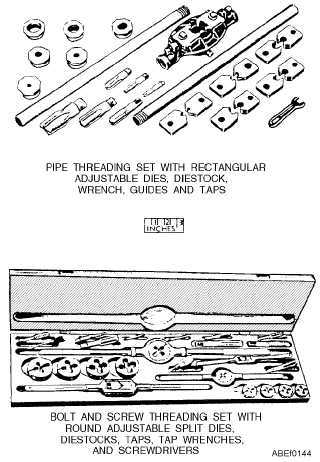

Threading sets are available in many different

combinations of taps and dies, together with diestocks,

tap wrenches, guides, and necessary screwdrivers and

wrenches to loosen and tighten adjusting screws and

bolts. Figure 1-58 illustrates typical threading sets for

pipe, bolts, and screws.

Never attempt to sharpen taps or dies. Sharpening

of taps and dies involves several highly precise cutting

processes that involve the thread characteristics and

chamfer. These sharpening procedures must be done by

experienced personnel to maintain the accuracy and the

cutting effectiveness of taps and dies.

Keep taps and dies clean and well oiled when not in

use. Store them so that they do not contact each other or

other tools. For long periods of storage, coat taps and

dies with a rust-preventive compound, place in

individual or standard threading set boxes, and store in

a dry place.

REVIEW QUESTIONS

Q25.

Identify the different types of taps.

Q26.

What are taper taps used for?

Q27.

Identify the different types of dies.

Q28.

What are two-piece rectangular pipe dies

used for?

1-36

Figure 1-57.—Adjustable die guide and ratchet diestocks.

Figure 1-58.—Tap and die thread sets.